Immersion heaters are used to heat liquids inside tanks or other containers. The installation may be threaded, flanged, or over the side. A resistance heating wire is enclosed in a ceramic jacket, encircled by a sheath to create immersion heaters. The sheath may be constructed from cast iron, copper, stainless steel, PFA-coated steel, Incoloy, or titanium. The element heats the water around it as electricity passes through it. With immersion heaters, water is heated inside the tank directly, rising to the top as it becomes hot. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

At Dalton Electric Heating Co., Inc., we are proud to be a leading provider of high-performance electric heaters, serving various industries with innovative and reliable heating solutions. For decades, we have focused on designing and manufacturing durable products, including cartridge heaters, industrial heaters, and other custom thermal solutions, all built to meet the most demanding industrial ...

At Ryan Herco Flow Solutions, we take pride in providing high-performance fluid handling and filtration products, and our electric heaters stand out as an essential part of that mission. We specialize in electric heating solutions designed to deliver precise temperature control, reliability, and safety across a wide range of applications

More Immersion Heater Manufacturers

Types Of Immersion Heaters

Immersion heaters are a critical component in a variety of industrial, commercial, and residential heating applications. These electric heating devices are designed to efficiently heat liquids—and, in some cases, gases—by direct contact with a heating element. Understanding the different types of immersion heaters and their unique advantages is essential for selecting the right solution for your process heating needs.

Whether you’re searching for industrial electric immersion heaters for chemical processing, water immersion heaters for domestic hot water supply, or oil immersion heaters for petrochemical or lubrication systems, the right immersion heater design will directly impact system reliability, efficiency, and total cost of ownership. Below, explore the main categories and specialized variants of immersion heaters, their configurations, and their most suitable applications.

Over-The-Side Immersion Heaters

Over-the-side immersion heaters are specially engineered to be installed either at the side or the bottom of a water tank or process vessel, typically via the vessel opening at the top. Once installed, these immersion heaters allow fluid within the tank to circulate naturally, ensuring uniform heat distribution throughout the medium. Power can be supplied via terminal housings or durable lead wires, depending on system requirements.

Over-the-side immersion heaters are manufactured in a wide variety of heating element types and shapes, allowing them to be customized for a broad range of heating applications. These heaters are commonly used to heat water, hydraulic oils, solvents, electroplating baths, salts, and corrosive acids. Their design provides an extensive heated surface area within the tank, making them highly effective for large vessels. The portability and ease of removal of over-the-side heaters simplifies maintenance, cleaning, and replacement—an important factor for industries where process downtime must be minimized.

- Ideal for tanks where through-wall installation is not possible

- Common in cleaning tanks, degreasing baths, and plating operations

- Available with thermostatic controls for precise temperature regulation

- Suitable for temporary or mobile heating tasks

- Can be manufactured with corrosion-resistant materials for aggressive chemicals

- Great for applications requiring frequent tank changes or maintenance

When should you choose an over-the-side immersion heater?

If you need a portable tank heater or require flexibility for changing tanks or cleaning, over-the-side immersion heaters are often the top choice. These are also suitable for environments where tank wall penetration is undesirable or not permitted. Curious about sizing, voltage compatibility, or selecting the best sheath material for your fluid? Contact us for expert immersion heater selection guidance or request a quote from leading manufacturers.

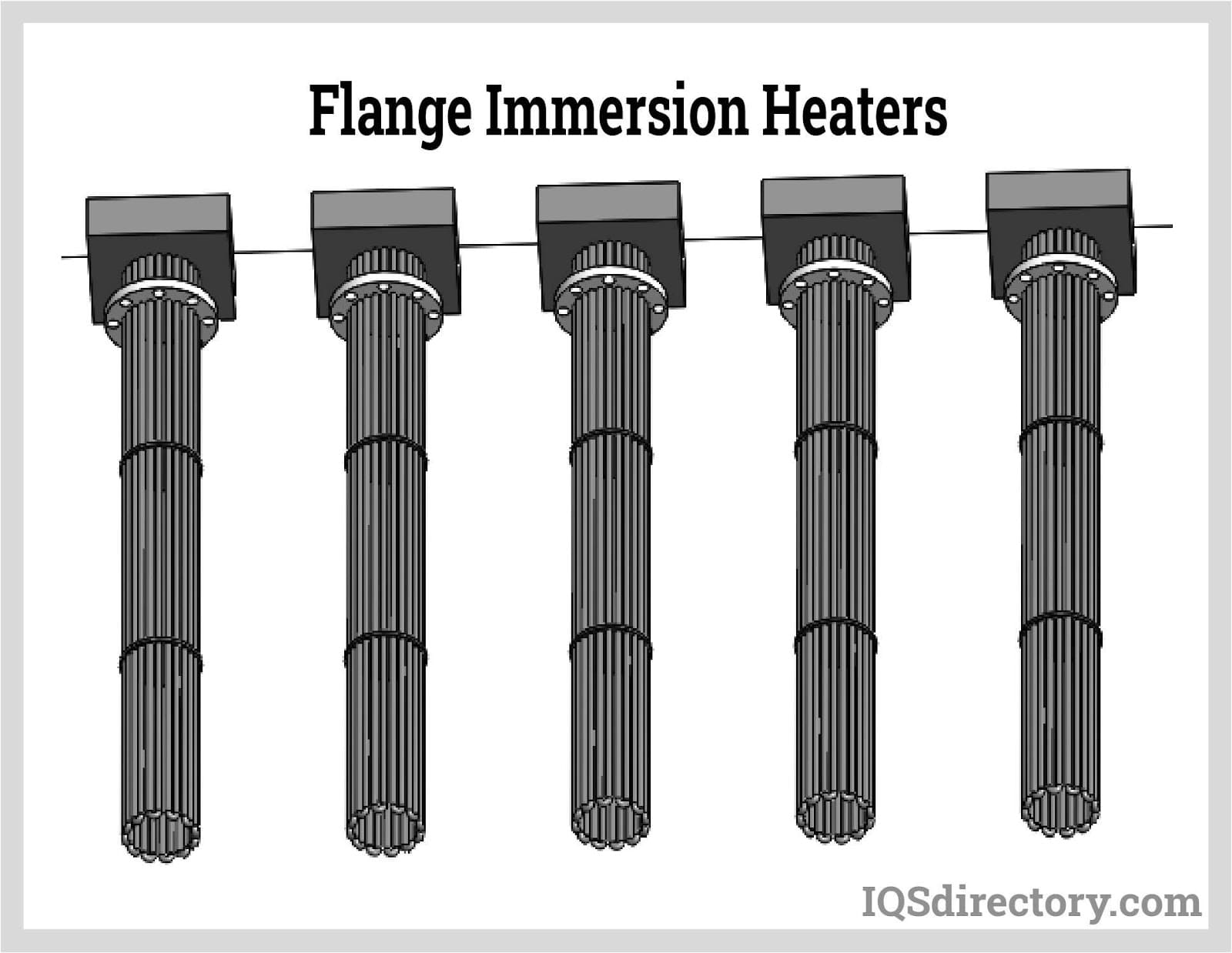

Flanged Immersion Heaters

Flanged immersion heaters are among the most widely used solutions for heating liquids such as heat transfer fluids, water, chemical solutions, and various oils. These industrial electric heaters are designed for easy installation and maintenance in tanks, reservoirs, or other pressurized vessels. The direct immersion design of flanged heaters provides rapid heat transfer, reduces energy consumption, and allows for precise temperature control—critical for process heating efficiency and safety.

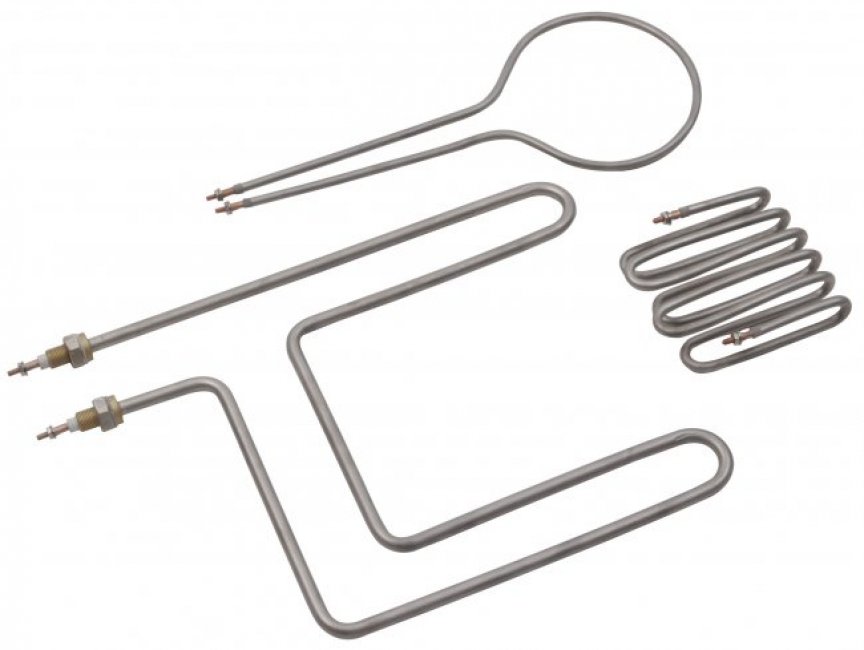

Each flanged immersion heater consists of multiple hairpin-bent tubular elements, which are welded or brazed into a robust flange (available in standard sizes such as 2”, 3”, 4”, 6”, and 8” diameters). The matching tank wall or nozzle must be fitted with a compatible flange for secure installation. Flanged heaters are highly customizable, offering a range of kilowatt ratings, voltages, sheath materials (such as stainless steel, Incoloy, or titanium), and terminal housing options to meet specific fluid compatibility and process requirements.

- Common in industrial water heating, chemical processing, and petrochemical plants

- Available in explosion-proof designs for hazardous locations

- Can be equipped with integrated temperature sensors or thermostats

- Ideal for large-scale process heating where reliability and efficiency are paramount

- Often chosen for high-pressure, high-temperature applications

- Compatible with a variety of process control systems and PLCs

Looking to specify a flanged immersion heater?

Explore options for custom flange sizes, sheath materials, and wattage ratings to match your application. Consider whether you need ASME-rated or pressure-certified flanges for your process tank. Not sure which configuration best fits your heating process? Ask our experts about flanged heater specifications and best practices.

Threaded Or Screw Plug Immersion Heaters

Screw-plug immersion heaters (also known as threaded immersion heaters) are an efficient solution for directly heating liquids in smaller tanks, pipelines, or vessels. These immersion heaters are particularly well-suited for applications such as defrosting, freeze protection, water heating, and process fluid temperature maintenance. The direct immersion approach results in high energy efficiency as heat is transferred directly into the medium being heated.

These heaters are constructed using hairpin-bent tubular elements, which are welded or brazed into a threaded plug (commonly 1”, 1.25”, 2”, or 2.5” NPT sizes). The threaded design allows for easy, secure installation into tank wall openings, pipe tees, or process nozzles. Most screw-plug immersion heaters come with weatherproof or explosion-proof terminal enclosures to support safe operation in industrial environments.

- Widely used in boilers, hot water storage tanks, hydraulic systems, and process lines

- Available with built-in thermostats for precise control

- Can be supplied in a variety of sheath materials to resist corrosion

- Simple installation and replacement—minimizing maintenance downtime

- Excellent for retrofitting into existing tanks or pipework

- Cost-effective solution for small-scale and point-of-use heating

Is a screw plug immersion heater right for your project?

If you require direct heating in a compact space or need to retrofit an existing tank or pipe, threaded immersion heaters offer a reliable solution. These are also suitable for freeze protection in pipelines or maintaining process temperatures in storage tanks. Discuss your application with a specialist to select the best screw-plug heater for your requirements.

Other Types of Immersion Heaters

In addition to the main categories above, there are other specialized immersion heaters designed for niche or advanced industrial heating requirements:

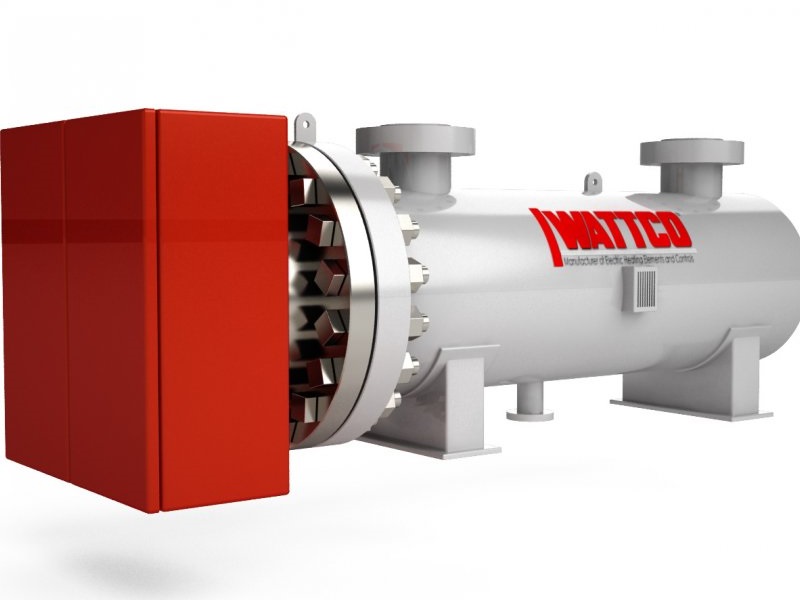

- Circulation Heaters: Integrate with pumps to heat fluids as they pass through a chamber—ideal for process heating loops and skid systems. These are widely used for applications requiring continuous recirculation and precise temperature management, such as fuel oil heating, water glycol heating, and chemical transfer systems.

- Quartz or Glass Immersion Heaters: Used for highly corrosive or ultra-pure fluid heating, such as in semiconductor manufacturing, laboratory settings, or plating baths containing aggressive acids and chemicals.

- High-Density Cartridge Heaters: Inserted directly into drilled holes for localized, high-watt-density heating. Suitable for molds, dies, and other industrial equipment requiring targeted thermal input.

- Steam-Generating Immersion Heaters: Specially built to rapidly generate steam for sterilization, cleaning, or humidification processes, often deployed in autoclaves and laboratory environments.

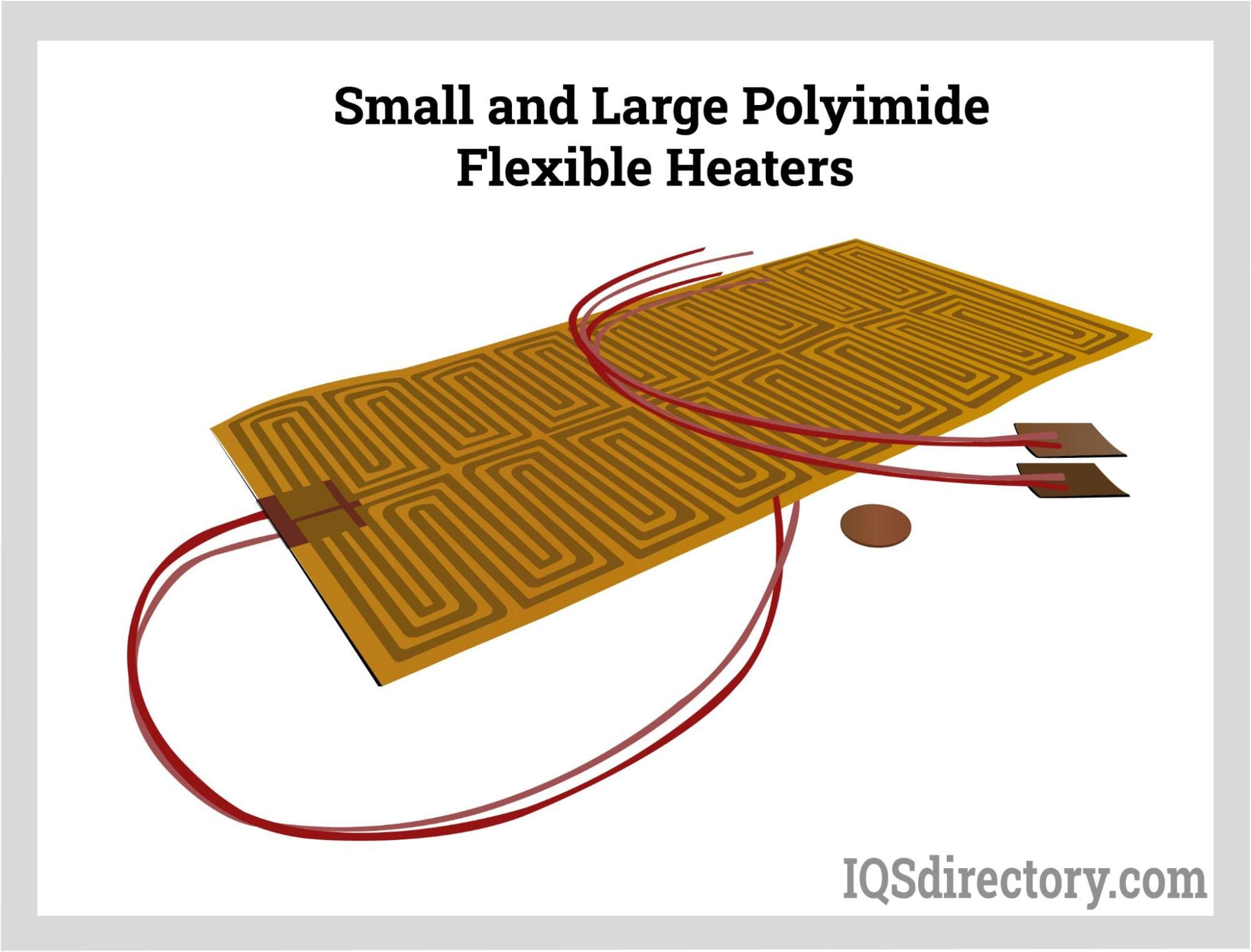

- Flexible Immersion Heaters: Designed to conform to irregular tank shapes or provide temporary heating in hard-to-reach places.

How do you choose the right type of immersion heater for your application?

Consider the following: fluid type and chemistry, tank or vessel dimensions, required temperature range, installation limitations, safety standards, and control requirements. Connect with an immersion heater expert for a detailed needs assessment and product recommendations.

Applications Of Immersion Heaters

Immersion heaters offer a wide range of applications in both domestic and commercial settings. Electric water heaters, air conditioners, instant hot water faucets, steam generators, reactors, and other corrosive or high-temperature usage are examples of household uses. In addition, immersion heaters have a wide range of industrial applications, including:

Are you searching for the best heating solution for your specific industry? Here’s how immersion heaters are applied in various sectors:

Cement Curing

Immersion heaters produce quick, reliable results by accelerating cement curing. Their ability to deliver consistent, controlled heat ensures uniform curing and improves the structural integrity of construction projects. For large-scale concrete pours, portable immersion heaters are often utilized to maintain the required temperature during cold weather, preventing costly delays and ensuring compliance with engineering standards.

Chemical Industry and Laboratories

Electric immersion heaters are essential for maintaining a constant temperature and avoiding freezing detergents, water, oils, and acidic or basic solutions. In laboratory environments, immersion heaters support sterilization, autoclaving, solvent evaporation, and drying of pharmaceutical products. Their precise temperature control and compatibility with aggressive fluids make them indispensable in research and process development.

Food Processing

Ceramic immersion heaters are used to manage moisture that encourages the growth of germs and pathogens that jeopardize the safety of food products. In addition, immersion heaters can disinfect containers and heat liquids so food processing operations can adhere to regulatory rules and quality requirements. Industries such as beverage production, dairy processing, and canning rely on immersion heating solutions for pasteurization and cleaning-in-place (CIP) systems.

Oil and Gas Industry

Immersion heaters warm up oil and petrochemical products without altering their structural integrity, allowing them to flow at low temperatures. They are essential for viscosity control in storage tanks, separation units, and pipelines, preventing blockages and ensuring uninterrupted production. Explosion-proof immersion heaters are often required for hazardous area installations.

Wastewater Management

Immersion heaters keep water from freezing in reservoirs and pipes during cold weather to prevent water treatment from failing. They also assist in sludge dewatering, chemical dosing, and biological treatment processes by maintaining optimal process temperatures.

Additional Common Applications

- HVAC Systems: Used in air handling units for humidification and freeze protection.

- Industrial Cleaning Equipment: Provide heat for ultrasonic cleaning, degreasing baths, and parts washers.

- Renewable Energy Systems: Heat transfer fluids in solar thermal storage tanks or geothermal loops.

- Pharmaceutical Manufacturing: Support sterile processing and temperature-sensitive reactions.

- Brewing and Distillation: Control mash and fermentation temperatures for product consistency.

- Electroplating and Anodizing: Maintain bath temperatures for high-quality metal finishing.

- Mining and Mineral Processing: Heat process solutions and prevent crystallization in leaching operations.

- Aquaculture: Maintain optimal water temperatures in fish farming tanks.

- Laboratory Testing: Deliver stable, precise heating for sample analysis and material testing.

Wondering if immersion heaters are right for your application?

Browse our comprehensive guide to immersion heater applications or speak to an industrial heating specialist for tailored recommendations. If you’re not sure which immersion heater suits your tank material, chemical compatibility, or process safety needs, we’re here to help you compare options.

Benefits of Immersion Heaters

Modern immersion heaters are engineered to deliver a host of advantages in process and utility heating scenarios:

- Direct, Efficient Heat Transfer: Immersion heaters provide near-100% energy efficiency, as heat is transferred directly from the heating element to the fluid, minimizing losses.

- Precise Temperature Control: Integration with thermostats and sensors ensures accurate, repeatable heating for critical processes.

- Adaptability: Available in numerous shapes, sizes, materials, and mounting options to suit virtually any tank or fluid type.

- Low Maintenance Requirements: Robust construction and corrosion-resistant materials reduce downtime and enhance operational longevity.

- Fast Response Time: Capable of quickly raising process temperatures, supporting both continuous and batch operations.

- Safety: Many immersion heaters offer built-in thermal cutoffs, over-temperature protection, and explosion-proof enclosures for hazardous environments.

- Cost-Effectiveness: Lower initial investment and operating costs compared to indirect heating systems or fossil-fuel-based alternatives.

- Ease of Installation: Immersion heaters are simple to retrofit into existing tanks or process lines with minimal modifications.

- Scalability: Suitable for everything from laboratory beakers to massive industrial storage tanks.

Typical Use Cases

Immersion heaters are ideal for water heating (domestic and industrial), chemical process heating, oil tank temperature maintenance, bath heating for cleaning or plating, and countless other applications where control, efficiency, and reliability are paramount.

Are you evaluating electric immersion heaters versus gas-fired or steam heating? Immersion heaters are often preferable for applications requiring precise temperature uniformity, rapid heat-up, and minimal emissions. Looking for a comparison of immersion heater types, materials, or installation methods? Explore our step-by-step comparison guide.

What are the key decision factors when selecting an immersion heater?

- Fluid Compatibility: The chemical composition, viscosity, and corrosiveness of the fluid determine the optimal sheath material (stainless steel, titanium, Incoloy, etc.).

- Heater Sizing: Calculating the required wattage and surface area ensures rapid, even heating without damaging the fluid or heater.

- Tank or Vessel Configuration: Mounting options (over-the-side, flanged, screw plug) should match the available installation points.

- Temperature Controls: Integration with thermostats, sensors, or process controllers is essential for safety and efficiency.

- Certifications & Safety Standards: Applications in hazardous locations may require UL, CSA, ATEX, or IECEx-rated heaters.

- Maintenance Access: Consider ease of removal and cleaning, especially for fluids with scaling or fouling tendencies.

- Budget Constraints: Weigh initial costs against long-term operating efficiency and reliability.

- Environmental Considerations: Evaluate energy efficiency, emissions, and lifecycle costs in your selection process.

- Electrical Supply: Confirm voltage, phase, and amperage compatibility with your facility.

Advantages and Disadvantages Of Immersion Heaters

Immersion heaters are a highly controllable and efficient heating method, requiring comparatively low maintenance while offering exceptional adaptability to diverse environments. Their advanced heating efficiency and direct heat transfer make them preferable for many process and utility heating needs.

However, immersion water heaters typically lack built-in automatic shutoff functionality; if operated without sufficient fluid coverage, the heating coils can overheat and fail, resulting in costly repairs and downtime. It is recommended to pair immersion heaters with level sensors or thermal protection devices to enhance safety and equipment longevity.

- Advantages: High energy efficiency, fast heat-up, minimal energy loss, precise control, flexible installation, low maintenance, and long service life when properly maintained.

- Disadvantages: Risk of dry firing, potential for element scaling in hard water, sometimes limited by tank or vessel size and material compatibility, and the need for careful control and monitoring to prevent overheating.

How can you maximize the lifespan of your immersion heater?

Regular inspection and cleaning, pairing with level switches, and selecting the appropriate sheath material for your fluid are critical steps. Using water softeners or anti-scaling treatments for hard water and implementing preventive maintenance schedules can also extend heater life. Read our maintenance guide for expert tips on extending your heater’s performance and reliability.

Choosing the Proper Immersion Heater Manufacturer

To ensure you achieve the best results when purchasing an immersion heater, it is critical to select a reputable and experienced immersion heater manufacturer or supplier. Use our comprehensive directory of immersion heater manufacturers to compare companies, review business profile pages highlighting areas of expertise and capabilities, and access direct contact forms for requesting information or quotes.

When evaluating immersion heater companies, consider the following:

- Experience and Industry Focus: Look for manufacturers with a proven track record in your specific application area (chemical, food processing, oil & gas, etc.).

- Customization Capabilities: Can they provide custom wattages, voltages, mounting styles, and materials?

- Certifications and Compliance: Verify adherence to UL, CSA, CE, or industry-specific standards.

- Technical Support: Reliable manufacturers offer design assistance, troubleshooting, and after-sales service.

- Lead Times and Availability: Ensure the supplier can meet your project timeline, especially for custom or high-volume orders.

- Quality Assurance: Ask about manufacturing controls, test procedures, and warranty policies.

- References and Reviews: Check for case studies or customer testimonials relevant to your industry or application.

Each immersion heater manufacturer in our network features a business profile page and a patented website previewer so you can get an overview of their product range and manufacturing capabilities. After shortlisting, use our convenient RFQ form to contact multiple immersion heater companies in a single step—streamlining your procurement process.

Ready to find the best immersion heater for your needs?

Request a custom quote or speak with our technical specialists for personalized recommendations based on your application, budget, and performance requirements. Explore our educational resources, guides, and product catalogs for in-depth information on immersion heater selection, sizing, and installation.

Frequently Asked Questions About Immersion Heaters

- What are immersion heaters used for? Immersion heaters are used for heating liquids (water, oil, chemicals, etc.) in industrial, commercial, and residential applications. They are also used for freeze protection, process temperature maintenance, and rapid heat-up of process fluids.

- How do I size an immersion heater? Sizing involves calculating the energy required to raise the fluid to the desired temperature within a certain time, factoring in tank size, initial temperature, and heat losses.

- What maintenance is required? Regular inspection, cleaning, and ensuring heaters are always submerged during operation are essential. Periodic testing of control devices and inspection for signs of scaling or corrosion are also recommended.

- Can immersion heaters be used in hazardous locations? Yes, provided the heater is suitably rated (explosion-proof, ATEX, UL, etc.) for the specific environment. Always confirm compliance with site safety requirements.

- What safety features are recommended? Level sensors, thermal cutoffs, ground fault protection, and temperature controllers are strongly advised to prevent dry firing and overheating.

- What is the typical lead time for custom immersion heaters? Lead times vary by manufacturer and complexity, but most custom immersion heater orders can be fulfilled within 2–6 weeks. For urgent needs, ask about expedited manufacturing or in-stock models.

- Which sheath material is best for my application? Stainless steel is suitable for water and mild chemicals; Incoloy or titanium are recommended for corrosive or high-temperature fluids. See our sheath material compatibility guide.

- Can immersion heaters be controlled remotely? Yes, many modern immersion heaters can be integrated with remote monitoring, PLCs, or industrial IoT platforms for advanced control and diagnostics.

Still have questions?

Visit our Immersion Heater FAQ page or contact our team to discuss your unique application requirements, safety concerns, or product selection criteria. You can also request technical datasheets, installation instructions, or troubleshooting support for your specific immersion heater model.

Cartridge Heaters

Cartridge Heaters Industrial Electric Heaters

Industrial Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services