Electric heaters are any electric-powered devices used to create heat. Electric heat generation takes place when electricity is converted into thermal energy. During this conversion, an electric charge is conveyed by electrons through a medium. Inside the medium, the electrons collide with atomic particles from an electric heating element, and vibrate. These vibrations manifest as heat. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

At Dalton Electric Heating Co., Inc., we are proud to be a leading provider of high-performance electric heaters, serving various industries with innovative and reliable heating solutions. For decades, we have focused on designing and manufacturing durable products, including cartridge heaters, industrial heaters, and other custom thermal solutions, all built to meet the most demanding industrial ...

At Ryan Herco Flow Solutions, we take pride in providing high-performance fluid handling and filtration products, and our electric heaters stand out as an essential part of that mission. We specialize in electric heating solutions designed to deliver precise temperature control, reliability, and safety across a wide range of applications

More Industrial Electric Heater Manufacturers

Electric Heater Applications

Electric heaters are indispensable in modern industry and daily life, providing reliable and efficient heat across countless environments. In industrial settings, electric heaters play a critical role in process heating, such as maintaining precise temperatures in liquid tanks, facilitating the shaping and melting of raw materials, and keeping substances molten for extended periods. Manufacturing processes like plastic extrusion rely on electric heating elements to plasticize materials in tandem with natural friction. Other common industrial applications include packaging machinery, foam and metal fabrication, food processing lines, and water treatment facilities, where electric heaters ensure sanitary and consistent operation. Electric heaters are also vital in chemical processing, pharmaceutical manufacturing, and semiconductor fabrication, where precision thermal control is essential for product quality and regulatory compliance.

Beyond industrial uses, electric heaters are extensively deployed for comfort heating in both residential and commercial buildings. Whether it’s a portable space heater for a small office or a large central electric heating system for a warehouse, these units offer supplementary warmth and energy-efficient climate control. Specialized heaters—such as immersion heaters for water heating or air heaters for HVAC systems—address unique needs in laboratories, greenhouses, and cleanrooms. In commercial applications, electric heaters are often used in retail spaces, hospitality venues, and educational institutions to maintain comfortable indoor environments and supplement central heating systems in cold climates.

- Industrial process heating (melting, molding, drying, curing)

- Residential water and space heating

- Commercial HVAC systems

- Food service equipment (ovens, warmers, fryers)

- Medical and laboratory heating (incubators, sterilizers)

- Energy generation (pre-heating fluids in turbines)

- Greenhouse and agricultural heating

- De-icing and freeze protection for pipelines and roofs

- Electronics manufacturing (PCB soldering, reflow ovens)

- Paint curing and drying in automotive and aerospace industries

Need help selecting the right electric heater for your application?

Explore: What type of electric heater is best for industrial process heating? | How do I choose an energy-efficient space heater for my home or office? | What are the maintenance requirements for commercial electric heaters?

History of Electric Heaters

The evolution of electric heaters is deeply intertwined with the progress of electrical engineering and materials science. In the early 1890s, General Electric in America manufactured the first electric heaters, which utilized elongated glass bulbs—a recent invention—to generate warmth. While innovative, these fragile devices offered limited functionality and durability.

The breakthrough came with Albert Leroy Marsh’s invention of chromel (nichrome), a robust alloy capable of reaching temperatures up to 2552°F while resisting corrosion. This advancement transformed the efficiency, reliability, and safety of electric heaters, setting the stage for widespread adoption.

In the UK, Hebert John Dowsing pushed the boundaries of heating technology by adapting bulb heaters into an all-electric cooking and room heating system as early as 1891. Dowsing’s innovation, which featured a copper-backed heater for gradual heat radiation, marked a significant leap in domestic heating and paved the way for future developments.

The electric water heater was pioneered by Norwegian engineer Edwin Ruud in the late 19th century. Ruud’s model, which automatically heated stored water, became the foundation for the Ruud Manufacturing Company—still a leader in water heating technology today.

By 1912, the emergence of portable heaters and the patenting of central heating systems by Alice Parker (1919) revolutionized home heating. Innovations continued through the 1930s with the addition of electric fans and ductwork, giving rise to the first forced wall convection heaters. The mid-20th century saw further advances with the development of thermostatically controlled heaters and energy-efficient insulation materials, enabling greater control and safety.

The post-WWII era saw the introduction of radiant bar heaters (electric fires) and the storage heater in the 1960s, delivering consistent warmth with improved energy efficiency. Advancements in safety, portability, and smart technology—such as programmable thermostats and remote controls—have made modern electric heaters cleaner, safer, and more efficient, helping reduce dependence on fossil fuels and minimize environmental impact. Today, innovations like Wi-Fi-enabled heaters, smart home integration, and energy monitoring systems are shaping the future of electric heating solutions.

Curious about how electric heaters have evolved?

Research: What are the key technological milestones in electric heating? | How have safety standards changed over time? | What are the latest smart heater technologies?

Electric Heater Design

Production Process

The design and manufacturing of electric heaters are highly specialized, focusing on optimal heat generation, energy efficiency, and operational safety. The process begins with engineering the heating element—the heart of every electric heater. This may be a simple resistance coil or a complex assembly with ceramic insulators and advanced alloys such as nichrome or kanthal. The element type is chosen based on the end-use, whether for direct immersion, convection, or radiant applications, and customized to meet specific voltage, wattage, and temperature requirements.

Protective sheaths (often made from stainless steel, Incoloy, or other durable metals) encase the heating element, extending its life and safeguarding it from environmental stressors such as moisture, chemical exposure, or mechanical abrasion. High-performance insulation materials like ceramic, mica, or fiberglass are applied to maximize energy retention and minimize heat loss. The entire assembly may be integrated into a modular enclosure for easy installation, maintenance, and scalability. Advanced designs often incorporate thermal cutoffs, overheat protection, and integrated temperature sensors for enhanced safety and control.

Manufacturers optimize each design for specific use cases—factoring in heat transfer requirements, environmental exposure, and control system integration. Modern production processes leverage computer-aided design (CAD) and finite element analysis (FEA) to predict thermal performance and ensure compliance with strict industry standards.

- Custom-engineered heating elements for unique applications

- Sheath and insulation material selection for durability

- Integration with digital controls, programmable thermostats, and safety features

- Modular and scalable designs for industrial and commercial settings

- Compliance with international standards (UL, CE, RoHS, ISO)

Materials

Material selection is a critical aspect of electric heater performance. Commonly used conductive materials include nickel, stainless steel, and aluminum—each offering unique advantages in conductivity, corrosion resistance, and mechanical strength. Non-ferrous alloys such as Incoloy and copper are often chosen for their resilience in demanding industrial or corrosive environments. For insulation, ceramic remains the gold standard thanks to its high thermal resistance and electrical insulating properties, though mica and fiberglass are also widely used. Silicone rubber is employed in flexible heaters, and PTFE (Teflon) is used for chemical resistance in harsh environments.

These choices directly impact the heater’s lifespan, energy efficiency, and suitability for specific operating environments, such as high-moisture areas or applications requiring rapid thermal cycling. Food-grade materials are specified for sanitary applications in food processing, while explosion-proof designs are mandatory for hazardous locations in oil and gas industries.

Design Considerations and Customization

Selecting or customizing an electric heating system involves a detailed assessment of user requirements and operating conditions. Key considerations include:

- The substance or space to be heated (air, water, oil, materials, or specific rooms)

- Required operating temperature and heat-up/cool-down rates

- Energy efficiency goals and allowable watt density

- Projected lifespan and maintenance requirements

- Environmental conditions (humidity, exposure to chemicals, vibration, ambient temperature)

- Integration with control systems (thermostats, timers, sensors, building automation systems)

- Electrical requirements (voltage, phase, current draw)

- Compliance with local, national, and international safety standards

Manufacturers use this information to recommend the ideal heating element type, wattage, size, and control accessories for each application. Whether you need a custom-built process heater for a production line, a duct heater for HVAC upgrades, or a portable ceramic heater for an office, expert guidance ensures safety, efficiency, and regulatory compliance. Many suppliers offer engineering support, prototyping, and on-site installation services to guarantee optimal results.

Want to design a custom electric heater?

Ask: What specifications are most important for my industry? | How do I balance performance with energy savings? | Can I integrate electric heaters with my building automation system?

Types of Electric Heaters

The electric heater market is robust and continually evolving, offering numerous specialized products for different heating challenges. Below is an overview of the most common electric heater types, their features, and best-use scenarios:

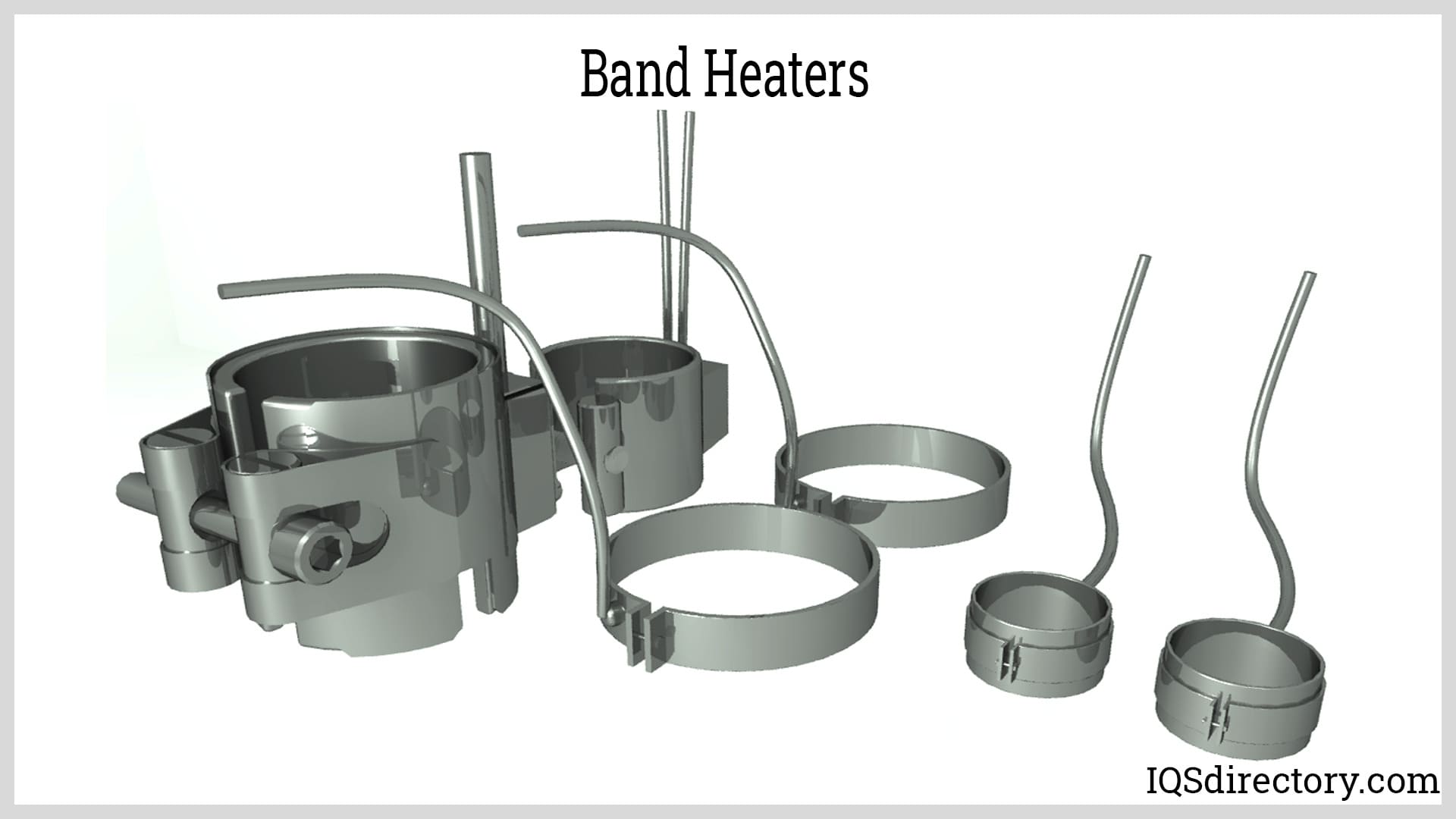

- Band Heater: Compact devices designed to wrap around pipes, nozzles, or tubes, delivering targeted conductive heat. Frequently used in plastic and metal forming—such as extrusion and injection molding—band heaters can reach temperatures between 300℉ and 1400℉. They also melt ice and prevent freezing in industrial settings. Ideal for: Plastics processing, pipe heating, and freeze protection.

- Strip Heater: Economical, durable heaters mounted directly onto equipment or within enclosures. Strip heaters are ideal for thawing, drying, baking, and air heating. Variations include finned and circular models for enhanced airflow or heating cylindrical objects. Use in: Food warming, packaging machinery, and ovens.

- Process Heater: Versatile electric heaters for direct or indirect heating of raw materials, surfaces, or fluids. Used in refining, molding, curing, and surface treatment processes. Common in: Chemical plants, oil refineries, paint curing lines.

- Cartridge Heater: Cylindrical, high-density heaters that fit into drilled holes in metal components. Essential for thermoforming, die cutting, sealing, and mold heating in manufacturing equipment. Suited for: Injection molds, hot stamping, seal bars.

- Radiant Heater: Heaters that emit infrared energy, warming objects and people without direct contact. Commonly used for spot heating, outdoor patios, and industrial drying. Oil-filled radiant heaters combine radiant and convective principles for sustained warmth. Popular for: Warehouses, outdoor restaurants, and paint drying booths.

- Immersion Heater: Designed for direct heating of liquids or solids by immersion. Known for safety, efficiency, and rapid heat transfer—ideal for large tanks in chemical, food, or water treatment industries. Choose for: Water heating, chemical baths, oil tanks.

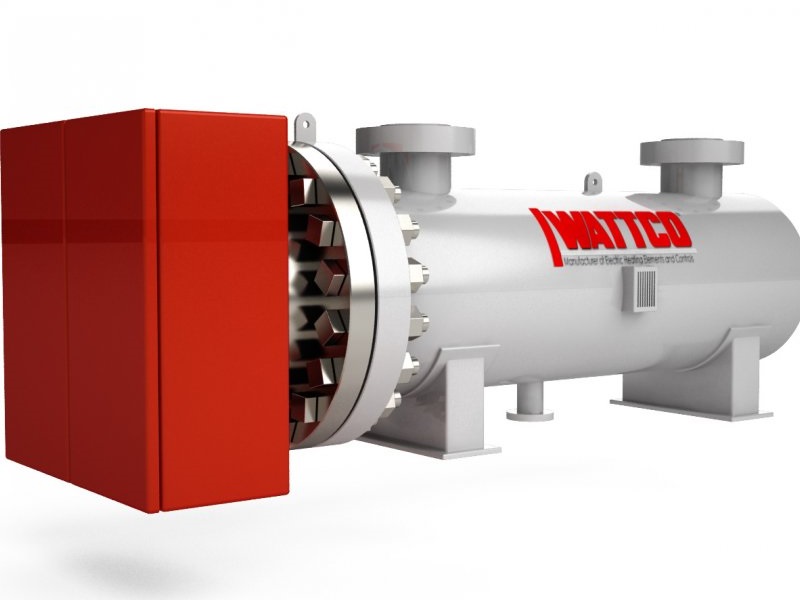

- Circulation Heater: Heaters that warm moving liquids or gases within a closed loop, often used for preheating fuel, oil, or water in processing plants. Great for: Boiler feedwater, fuel oil heating, and gas preheating.

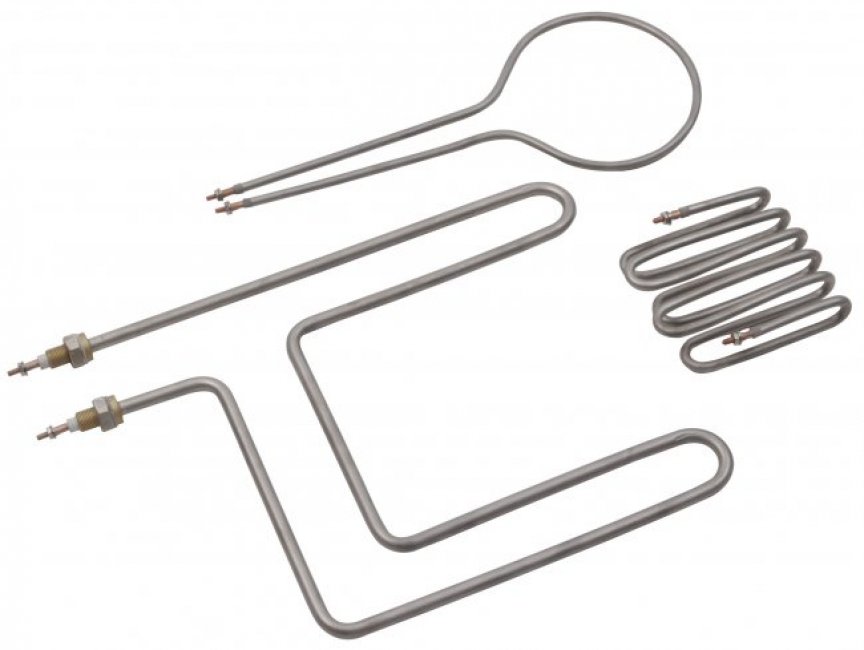

- Tubular Heater: Cylindrical elements with internal coils and magnesium oxide insulation for efficient heat distribution. Can be mounted for conduction, convection, or radiant heating in ovens, ducts, and appliances. Application: Industrial ovens, HVAC systems, and heat tracing.

- Air Heater: Used to elevate air temperature in confined or open spaces, including duct heaters in HVAC systems and fan-assisted units for manufacturing processes. Perfect for: Air handling units, drying tunnels, and space heating.

- Drum Heater: Specialized for maintaining or raising the temperature of drum-contained substances, such as chemicals or food products, during storage or transport. Use cases: Adhesive storage, oil drums, and food ingredient transport.

- Water Heater: Available in storage, tankless, solar, geothermal, and point-of-use varieties. Provide hot water for residential, commercial, and industrial needs. Popular for: Homes, hotels, factories, and laboratories.

- Ceramic Heater: Employs ceramic heating elements and aluminum fins, plus a fan, for rapid, efficient convective heat. Commonly found in portable space heaters and office environments. Best for: Spot heating in offices, workshops, and homes.

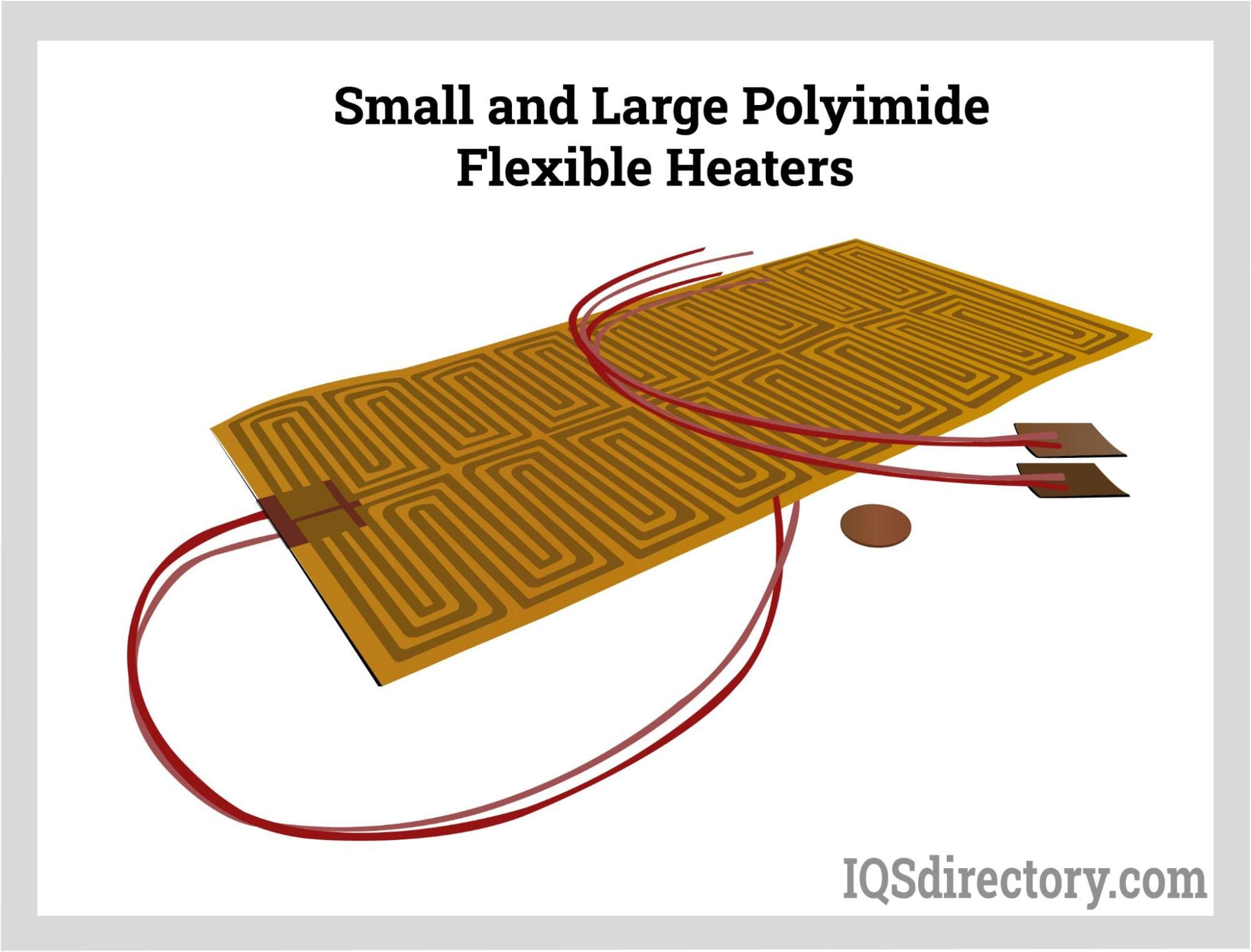

- Flexible Heater: Thin, bendable heaters made of silicone rubber or polyimide, designed for custom shapes and surfaces. Ideal for: Aerospace, electronics, and medical device heating.

- Infrared Heater: Uses quartz or carbon elements to generate radiant heat, rapidly warming people and objects directly. Perfect for: Outdoor patios, warehouses, and industrial drying.

Looking for a heater for a specific application?

Try: Which electric heater is best for water treatment plants? | Are ceramic heaters the most efficient for office use? | What type of heater is recommended for hazardous environments?

Electric Heater Advantages

Electric heaters offer a host of advantages, making them an attractive choice for both consumers and commercial buyers:

Versatility

Electric heaters are adaptable to a wide range of environments and heating requirements. Their modular design allows customization for unique shapes, sizes, and power demands—whether you need to heat air, water, oil, or industrial materials. This flexibility makes them suitable for everything from space heating in homes to process heating in factories. Electric heaters can be engineered for portable, wall-mounted, ceiling-mounted, or in-floor applications, and are available in both standard and custom configurations.

Environmental Friendliness

Compared to combustion-based systems (petroleum, natural gas, coal, or wood), electric heaters are a greener solution. They emit no CO2, smog, or hazardous gases at the point of use, supporting cleaner indoor air and contributing to reduced carbon footprints. When powered by renewable electricity, they offer a nearly emission-free heating solution for sustainability-conscious organizations. Many modern electric heaters are designed to work with solar power or smart grid systems, further reducing environmental impact.

Energy Efficiency

Electric heaters convert nearly all consumed electricity into usable heat, unlike fuel-based systems that lose energy through exhaust or incomplete combustion. This translates to higher operational efficiency, lower energy bills, and a smaller environmental impact, especially in well-insulated spaces or as part of a hybrid heating strategy. Zone heating with electric units allows you to warm only the areas in use, further maximizing energy savings. Many products have earned ENERGY STAR® or equivalent certifications, assuring buyers of top-tier efficiency.

Safety and Reliability

With no open flames or combustible fuels, electric heaters minimize risks of fire, explosion, or carbon monoxide poisoning. Their simple design—with few moving parts—promotes long-term reliability and minimal maintenance. On average, electric heaters last 15 years or more, making them a cost-effective investment for commercial and residential users alike. Many models come with overheat protection, tip-over switches, and child safety locks.

Fast Response and Precise Control

Electric heaters typically deliver heat almost instantaneously, reaching set temperatures faster than many fuel-based options. Advanced control systems, including programmable thermostats, Wi-Fi-enabled interfaces, and remote controls, allow users to fine-tune heating schedules, monitor performance, and optimize energy use from anywhere.

Want to maximize the benefits of electric heating?

Ask: How can I reduce my carbon footprint with electric heaters? | What are the safest electric heaters for home use? | Which electric heaters are eligible for energy efficiency rebates?

Electric Heater Accessories

Enhance your electric heater’s performance, safety, and control with a variety of essential accessories:

Thermostats

Thermostats regulate heater operation by monitoring ambient temperatures and cycling the unit on or off for precise climate control. Programmable thermostats allow users to schedule temperature changes throughout the day, maximizing both comfort and energy savings. For commercial applications, networked thermostats enable centralized management of multiple units, and integration with building automation systems (BAS) is often available for large-scale facilities.

Thermocouples

Thermocouples act as safety devices, detecting the presence of a pilot flame (in hybrid systems) or monitoring system integrity. In electric heaters, they provide an extra layer of protection by shutting down the unit in the event of overheating or power failure. Some advanced heaters use thermistors or RTDs (Resistance Temperature Detectors) for even greater precision and reliability.

Gaskets and Seals

High-quality gaskets and seals prevent air, liquid, or heat leakage, improving efficiency and minimizing energy loss. These are critical in convection or forced-air heaters, as well as in immersion and drum heating applications where tight containment is necessary. Silicone, neoprene, and PTFE seals are common in harsh or high-temperature environments.

Baffles

Baffles direct and distribute heat evenly within heaters, improving overall effectiveness by targeting warmth where it’s needed most. This is especially important in industrial process heating and radiant heating systems. Proper baffle design can reduce energy consumption and extend heater lifespan by ensuring uniform temperature distribution.

Temperature Controls

Knobs, switches, and digital controls allow users to adjust output precisely, ensuring optimal performance in diverse environments. For sensitive applications—like greenhouses or manufacturing plants—advanced temperature controls help maintain strict conditions for quality and safety. Touchscreen interfaces and mobile app controls are now available in many modern electric heaters, offering unprecedented convenience.

Choosing the right accessories can increase energy savings, extend heater life, and ensure your system operates safely and efficiently.

Explore: Which thermostat is best for my electric heater? | How do baffles improve heater performance? | What are the benefits of Wi-Fi-enabled temperature controls?

Electric Heater Installation

Installing an electric heater is typically fast and straightforward, often requiring only a standard electrical connection. Stand-alone units can be easily plugged in or hardwired, while modular designs allow for seamless integration into existing HVAC systems or industrial processes. This simplicity reduces upfront costs and makes it easy to expand or upgrade as business needs evolve. For large-scale or industrial installations, professional electricians may be required to meet local electrical codes and ensure safe, reliable operation. Wall-mounted and ceiling-mounted heaters can help maximize floor space in commercial environments, while in-floor radiant systems are increasingly popular for luxury residential and office spaces.

Considering new electric heating for your facility?

Ask: What are the installation requirements for large industrial heaters? | Can I retrofit electric heaters into a legacy HVAC system? | How do I prepare my electrical system for electric heating upgrades?

Proper Care of Electric Heaters

Cleaning and Maintenance

Regular maintenance is key to maximizing the lifespan and efficiency of electric heaters. The primary threats are contamination (dust, debris, or moisture) and excessive thermal cycling. Inspect heaters frequently to remove contaminants, monitor for unusual operation, and keep a maintenance log to track use and temperature swings. Avoid unnecessary movement or shocks to minimize wear and tear. For industrial heaters, periodic insulation resistance testing and thermal imaging inspections are recommended to detect early signs of failure.

Optimizing Performance

Choose the appropriate sheath material, maximum sheath temperature, and watt density for your application to optimize performance and longevity. Compatibility between heater design and operating environment is crucial for safety and efficiency. Use only manufacturer-approved replacement parts, and ensure that control systems are calibrated and functioning correctly. For facilities with multiple heaters, consider implementing a preventive maintenance schedule to reduce downtime and repair costs.

Want expert maintenance tips?

Explore: How often should I inspect my electric heaters? | What cleaning methods are safest for electric heating elements? | How do I troubleshoot a malfunctioning industrial heater?

Electric Heater Standards

Compliance with federal, state, and industry standards is essential for safety, efficiency, and regulatory approval. Residential electric water heaters in the U.S. must meet Department of Energy (DOE) efficiency standards and adhere to EPA emissions regulations. Additional certifications from organizations like ANSI, NFPA, and the National Electric Code (NEC, ANSI/NFPA 70) may apply, especially for commercial or industrial installations. Internationally, certifications such as CE Marking (Europe), CSA (Canada), IEC (global), and RoHS (Restriction of Hazardous Substances) may be required for export or specialized uses.

Always confirm applicable requirements with your supplier and local authorities to ensure code compliance and safe operation.

Ask: What certifications are required for electric heaters in my state? | How do international standards differ for industrial heaters? | What safety features should be prioritized for workplace compliance?

Things to Consider Regarding Electric Heaters

Maintaining the right indoor temperature is crucial for comfort, productivity, and safety—especially in harsh climates. In regions with extreme cold, such as Canada, a combination of robust building insulation and supplementary electric heating ensures a pleasant and energy-efficient environment. Modern electric heaters are lightweight, portable, and engineered for maximum heat transfer efficiency, making them suitable for targeted use in specific rooms or as backup to central systems. In commercial and industrial settings, electric heaters support process stability and equipment protection by preventing condensation, freezing, or temperature fluctuations.

Despite their versatility, selecting the right electric heater involves careful consideration of:

- Room or area size

- Desired temperature increase

- Power supply and energy consumption

- Heating element type and configuration

- Portability and installation constraints

- Safety features and certifications

- Control options (manual, programmable, remote)

- Noise level and aesthetics (for residential and office spaces)

Because electric heaters are energy-efficient and cost-effective when used appropriately, it pays to evaluate all relevant factors before purchasing. Consulting with experienced suppliers or using online heater sizing calculators can help determine the best solution for your needs.

Determine the Heat Requirement

Accurate sizing is critical to avoid wasted energy or insufficient heating. As a rule of thumb, allow about 10 watts per square foot of floor space. Oversizing leads to unnecessary energy use and higher bills, while undersizing may result in inadequate warmth and longer run times. For industrial processes, heat load calculations should account for ambient losses, material properties, and process timing.

Look for Features of an Energy-Efficient Electric Heater

To achieve maximum savings and optimal performance, prioritize the following features:

- High Heat Transfer Rate and Capacity: Ceramic, infrared, and oil-filled radiant heaters are among the most efficient, rapidly transferring heat while retaining warmth. Low thermal mass designs can also reduce warm-up times.

- Programmable Thermostat and Timer: Allows precise control of temperature and operation schedules, automatically cycling the heater to maintain comfort and minimize waste.

- Multiple Heat Settings: Adjustable output lets you tailor heating to changing needs, further reducing energy consumption.

- Automatic Shutoff and Overheat Protection: Enhances safety and prevents energy waste or fire hazards.

- Wi-Fi or Smart Home Integration: Enables remote monitoring and scheduling for ultimate convenience and efficiency.

Calculate Energy Costs

Estimate operational costs by multiplying your heater’s wattage by the hours of use, then dividing by 1,000 to convert to kilowatt-hours (kWh). Multiply the result by your local electricity rate for a realistic projection of monthly expenses. Consider the impact of insulation, outdoor temperatures, and supplemental heating when evaluating total cost of ownership.

Electric heater efficiency is maximized when used as a supplemental heat source in well-insulated spaces, working alongside central heating to maintain comfort with minimal energy use. Many users research total cost of ownership (TCO) and lifecycle energy savings when comparing electric heating to gas or oil systems.

Want to compare electric heating costs?

Try: How much does it cost to run a 1500W electric heater for 8 hours? | Which electric heater offers the lowest annual operating expense? | Are there government incentives for upgrading to efficient electric heaters?

Choosing the Proper Electric Heater Provider

Optimizing your electric heating solution starts with choosing the right supplier. Consider providers with:

- Proven experience in your industry or application area

- Ability to customize heaters for specific requirements

- Strong technical support and after-sales service

- Compliance with all relevant standards and certifications

- Positive reviews and recommendations

- Comprehensive product documentation and installation guidance

- Energy efficiency and sustainability initiatives

Communicate your needs clearly—material preferences, power output, temperature range, control requirements—and ask detailed questions about product performance and safety. Evaluate your interactions for responsiveness and expertise; select a manufacturer committed to your satisfaction and long-term success. Many reputable suppliers offer free consultation services and can provide custom quotes based on your project details.

Ready to source the ideal electric heater?

Browse our list of electric heater manufacturers and suppliers at the top of this page, select several reputable providers, and request quotes or detailed consultations. Make an informed decision and move forward with confidence.

Check out our Electric Transformers website

Check out our Power Cords website

What are the main industrial applications of electric heaters?

Electric heaters are widely used in industrial settings for applications such as process heating, maintaining precise temperatures in tanks, plastic extrusion, packaging machinery, foam and metal fabrication, food processing lines, and water treatment facilities. They are also critical in chemical processing, pharmaceutical manufacturing, and semiconductor fabrication where thermal control is essential.

How have electric heaters evolved over time?

Electric heaters have evolved from fragile glass bulb designs in the 1890s to robust nichrome elements, portable models, and central heating systems. Technological advancements have introduced thermostatic control, energy-efficient insulation, radiant bar heaters, and smart technology features such as Wi-Fi integration and programmable thermostats, improving safety, efficiency, and convenience.

What factors should be considered when designing or choosing an electric heater?

Important considerations include the substance or space to be heated, required operating temperature, heat-up and cool-down rates, energy efficiency goals, projected lifespan, maintenance needs, environmental conditions, electrical requirements, integration with controls, and compliance with safety standards. Proper material and component selection is vital for performance and durability.

What are the most common types of electric heaters and their uses?

Common types include band heaters (for pipe and nozzle heating), strip heaters (for thawing and baking), process heaters (for fluids and surfaces), cartridge heaters (for molds and dies), radiant and infrared heaters (for spot or outdoor heating), immersion and circulation heaters (for liquids), air and duct heaters (for HVAC), drum heaters (for stored substances), water heaters, ceramic, and flexible heaters for specialized applications.

What are the advantages of using electric heaters?

Electric heaters offer versatility, environmental friendliness, high energy efficiency, safety (no open flames or emissions), reliability, long service life, fast response, and precise control. They are suitable for varied applications, can be powered by renewable energy, and are cost-effective, especially for supplemental and zone heating.

What accessories can enhance the performance and safety of electric heaters?

Accessories such as thermostats, thermocouples, gaskets, seals, baffles, and advanced temperature controls can improve performance, safety, and efficiency. Programmable thermostats and Wi-Fi-enabled controls provide greater convenience and allow scheduling and centralized management, especially in commercial installations.

How do you maintain and optimize the performance of electric heaters?

Regular inspection, cleaning, and testing (such as insulation resistance and thermal imaging) are essential. Choose appropriate sheath materials and watt density, use only approved replacement parts, and keep control systems calibrated. For multiple units, implementing a preventive maintenance schedule reduces downtime and extends heater lifespan.

What standards and certifications must electric heaters meet?

Electric heaters must comply with federal, state, and international standards such as DOE efficiency standards, EPA emissions regulations, ANSI/NFPA electrical codes, UL, CE, RoHS, IEC, and CSA certifications. These standards ensure safety, energy efficiency, and regulatory compliance for residential, commercial, and industrial applications.

Cartridge Heaters

Cartridge Heaters Industrial Electric Heaters

Industrial Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services