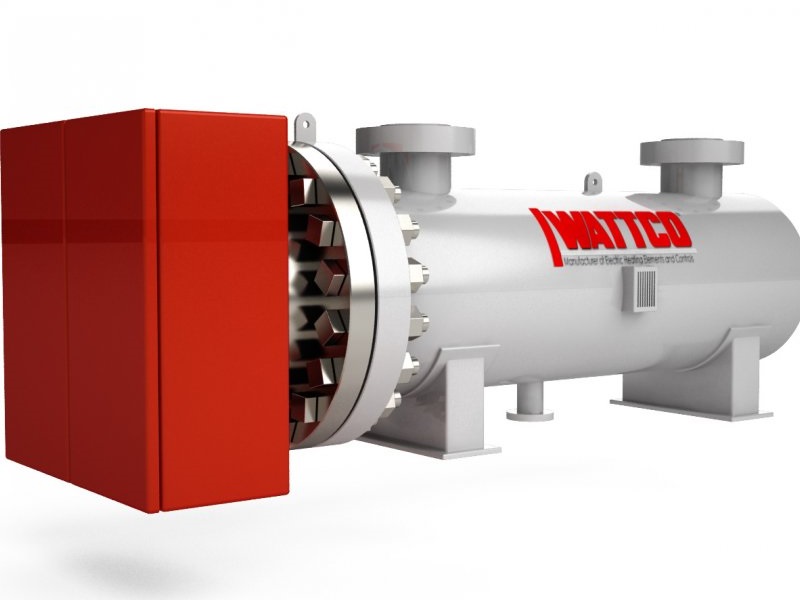

Circulation heaters are a vital tool for industries that require precision heating for their operations. The consistent heat supplied by circulation heaters serves a wide variety of applications. The strength and durability of circulation heaters have made them a central part of providing heat for processes that include oil and gas refining and the production of food and beverages. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

At Dalton Electric Heating Co., Inc., we are proud to be a leading provider of high-performance electric heaters, serving various industries with innovative and reliable heating solutions. For decades, we have focused on designing and manufacturing durable products, including cartridge heaters, industrial heaters, and other custom thermal solutions, all built to meet the most demanding industrial ...

At Ryan Herco Flow Solutions, we take pride in providing high-performance fluid handling and filtration products, and our electric heaters stand out as an essential part of that mission. We specialize in electric heating solutions designed to deliver precise temperature control, reliability, and safety across a wide range of applications

More Circulation Heater Manufacturers

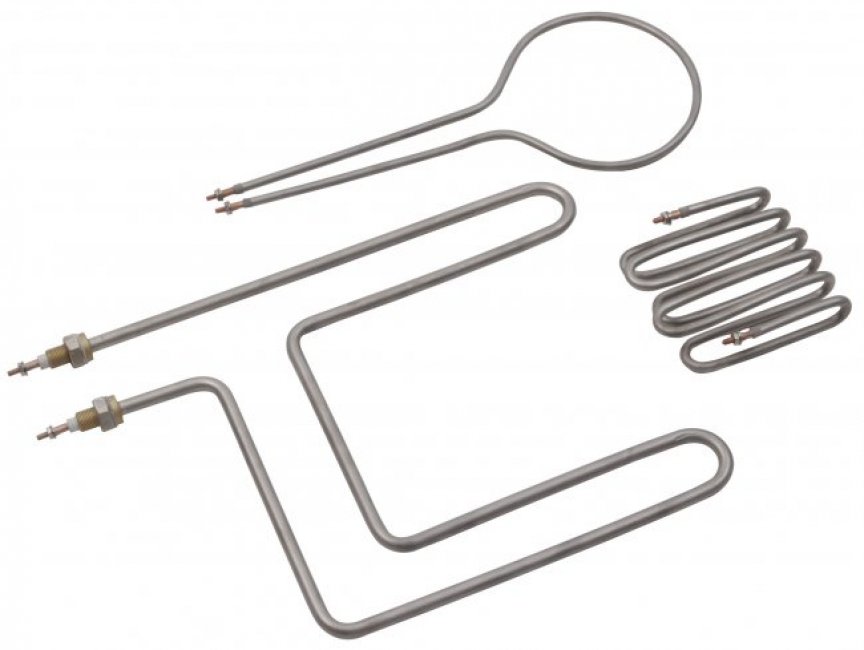

The simple heating functions of circulation heaters are produced by a complex structure of tubes and metal sheathing that is designed for high performance operations in some of the most stressful environments.

The many types of circulation heaters make it difficult to choose one that exactly fits the requirements of an application. The wide selection necessitates careful consideration regarding the type of circulation heater that best fits a process. Circulation heater providers work closely with their clients to supply data, expertise, and guidance regarding the many designs of circulation heaters. Before entering into discussions with trained professionals, it is important to have a basic understanding of the facts related to circulation heater selection.

How to Choose a Circulation Heater

Circulation heaters are made with different element sheath materials, vessel materials, terminal housings, and power and pressure ratings. The selection process requires consideration of the application to be served and its heat requirements, which determines the material from which a circulation heater is manufactured. In addition, the watt density of a circulation heater is directly related to the temperature requirements.

Materials used to produce a circulation heater should provide protection and enhance a circulation heater’s performance. In addition, the type of materials must be able to endure the product being heated in accordance with temperature, pressure, chemical resistance, corrosion, and oxidation. Common circulation heater materials are steel, stainless steel, and incoloy alloys 800 and 840. Manufacturers choose materials that enhance the heating capabilities of a circulation heater, aside from the protection and stability attributes.

-

Application Analysis

In order to select the proper heater for an application, a careful analysis of a circulation heater’s intended use has to be thoroughly examined. Such an evaluation includes a summary of the criteria required by an application. As with many industrial processes, the use of circulation heaters involves a unique combination of parameters with the main and obvious concern being the operating temperature. The correct sheath temperature maximizes the life of a circulation heater’s heating element and prevents the degradation of fluids.

There are different performance parameters that need to be studied when researching the aspects of a circulation heater. They include process specific conditions such as fluid flow rate, operating pressure, and required fluid outlet temperature. Additionally, maximum heater element sheath temperature, thermal conductivity, fluid viscosity, and thermal expansion coefficient need to be considered. Although some of this jargon may be new or confusing, knowledge of it can be beneficial during discussions with manufacturers and installers.

-

Fluid Flow Type

The fluid flow type also determines the type of circulation heater for an application. Laminar, turbulent, and transition are the three basic fluid flow types. Laminar fluid flow is smooth and follows a regular path with velocity, pressure, and flow properties remaining constant. As the designation turbulent implies, the turbulent flow type includes irregular changes and fluctuations with fluids continuously undergoing changes in magnitude and direction. The transition flow type is a middle ground between turbulent and laminar. Of the flow types, laminar happens the least due to its requirement of length, which cannot be accommodated by circulation heaters that are short.

-

Heat Transfer

The fluctuations between turbulent and laminar heat transfer changes from natural convection to forced convection. With natural convection, a fluid is heated and its density decreases. An increase in temperature causes a fluid to be lighter. Forced convection is the result of putting a fluid between differential pressure, forcing motion according to the laws of fluid mechanics. The two heating transfer types can work together or in opposition, with the most effective heat transfer occurring when they work together in a vertical vessel with a vertical upward flow. An understanding of the types of heat transfer affects the type of circulation heater for an application.

-

Watt Density

Watt density refers to the amount of heat generated by a circulation heater’s heating element. It is calculated by dividing the power of the heating element by the heated surface area. This calculation helps in determining the lifespan of a circulation heater, its size, and the types of elements being used. Watt density is affected by a heater’s operating temperature and industrial operations that involve corrosion.

Circulation heaters are chosen for a watt density that allows for achieving a safe operating temperature while maintaining the integrity of an application’s fluid. In most cases, lower watt densities are recommended, but recent developments have enabled manufacturers to produce circulation heaters with a higher watt density without reducing the lifespan. Variations in watt density are dependent on the preferences of customers, which can include standard watt densities or custom made circulation heaters.

-

Heater Orientation

Since circulation heaters can be oriented in multiple configurations, it is important to determine the desired positioning for the most efficient performance. There are general rules that are followed by circulation heater manufacturers when installing circulation heaters. For liquids, it is suggested that the heater be horizontal with the inlet and outlet connections facing upward with the inlet being positioned close to the terminal housing.

In the same vein, the position for liquids can be vertical with the terminal enclosure at the bottom and the inlet closest to the bottom, which ensures that elements are immersed. The orientation for gases is always horizontal with the inlet close to the terminal enclosure. The various orientations are designed to reduce the temperature in the terminal enclosure.

-

Temperature Controls

A basic aspect of all forms of circulation heaters is their temperature and operating control mechanism. The best controls enable users to quickly make adjustments to reach the targeted fluid temperature. A common type is a silicon-controlled rectifier (SCR) that enables the most precise temperature controls. Temperature controls sit on the outlet of a circulation heater and give operators immediate process feedback. When there is poor flow, temperature sensors should be placed on the sheath of the heating element to avoid being overwhelmed.

Factors Regarding the Purchase of a Circulation Heater

For a circulation heater that meets the needs of an application, it should adhere and comply with the stipulations listed here.

- Minimum and maximum operating temperatures are the initial considerations for purchasing a circulation heater.

- The viscosity, corrosivity and thermal properties of the material to be heated determine structural materials and the stability of a circulation heater.

- Pressure requirements influence the materials of a circulation heater.

- The type of circulation heater varies according to whether it is located indoors or outdoors.

- A clear understanding of mounting positions is necessary, since circulation heaters can be positioned vertically, horizontally, or sloped.

- The available power supply can vary between electrical and steam, with steam being rare but providing accurate heating.

- Climatic conditions influence a circulation heater’s structural material and placement.

- Circulation heaters for the 21st century are technologically advanced tools that have precision sensors and controls. It is important to choose a package that fits an application and the industry where a circulation heater will be used.

Circulation heaters are found in natural gas processing plants, hydrocarbon refineries, food and beverage preparation, and power generation plants. Manufacturers design and engineer them to meet the needs of a specific application and industry. There is a wide spectrum of materials that circulation heaters can heat. They are an industrial staple due to their ability to heat liquids and gases that range from nitrogen to oils and include water and hydrogen water. Regardless of their prevalence, in order to choose the proper circulation heater for an application, it is important that customers work with trained experts and be knowledgeable of the selection factors.

Cartridge Heaters

Cartridge Heaters Industrial Electric Heaters

Industrial Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services