Ceramic heaters are electric heaters that produce heat utilizing the resistive heating theory and a ceramic heating element consisting of a positive temperature coefficient (PTC). As current passes through ceramic materials, they have enough electrical resistance and thermal conductivity to create and conduct heat. In addition, they are powerful and long-lasting; as a result, they work effectively as a heating element. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

At Dalton Electric Heating Co., Inc., we are proud to be a leading provider of high-performance electric heaters, serving various industries with innovative and reliable heating solutions. For decades, we have focused on designing and manufacturing durable products, including cartridge heaters, industrial heaters, and other custom thermal solutions, all built to meet the most demanding industrial ...

At Ryan Herco Flow Solutions, we take pride in providing high-performance fluid handling and filtration products, and our electric heaters stand out as an essential part of that mission. We specialize in electric heating solutions designed to deliver precise temperature control, reliability, and safety across a wide range of applications

More Ceramic Heater Manufacturers

Ceramic Heaters: Comprehensive Guide to Types, Materials, Applications, and Buying Tips

Ceramic heaters are among the most popular electric heating solutions on the market today, offering a blend of safety, efficiency, and versatility for personal, residential, commercial, and industrial use. As more homeowners and businesses seek energy-efficient heating systems and alternatives to traditional convection or oil-filled radiators, ceramic heaters have emerged as a top choice for supplemental and primary heating. Whether you’re researching the best ceramic heater for a small room, evaluating industrial ceramic heating elements for manufacturing, or comparing portable ceramic space heaters for office or home use, this guide covers everything you need to know to make an informed decision.

At their core, ceramic heaters leverage advanced ceramic heating elements—often made from PTC (Positive Temperature Coefficient) ceramic composites—that not only act as superior electrical insulators but also conduct heat exceptionally well. Most modern ceramic heaters feature a combination of metal and ceramic materials, allowing for quick heat-up times, consistent temperature control, and reliable safety features. Unlike uninsulated resistance wire heaters, ceramic models significantly reduce energy losses, offering superior performance and lower power consumption. Their self-regulating nature—where power output drops as the target temperature is approached—makes them one of the safest and most energy-efficient electric heating technologies available today.

Curious about how ceramic heaters work, what makes them different, and why so many buyers choose them over alternative heating systems? Read on for a deep dive into the science, design, benefits, and best use cases for ceramic heating technology. If you’re comparing electric space heaters, seeking energy-efficient home heating options, or wondering about the best portable heaters for your office or workshop, this guide is designed to answer your most pressing questions and help you navigate the ceramic heater marketplace with confidence.

Types of Ceramic Heaters: Which Is Right for You?

If you're searching for answers to "What are the different types of ceramic heaters?" or "Which ceramic heater is most efficient for my needs?", you’ll find that ceramic heater technology generally falls into two main categories, each optimized for specific applications and environments. Understanding these types is essential for buyers who want to maximize comfort, energy savings, and safety in their chosen setting.

-

Convective Ceramic Heaters

Convective ceramic heaters—commonly known as ceramic space heaters or fan-forced ceramic heaters—feature a PTC ceramic heating element encased in aluminum fins or baffles. A high-efficiency fan draws in ambient air, pushes it across the heated ceramic surfaces, and circulates warm, even air throughout the space. These models are especially effective for quickly raising the temperature in a closed room, office, or workshop, making them a go-to choice for supplemental heating in homes, apartments, commercial offices, and classrooms. Advanced models offer oscillation, digital thermostats, and multi-speed fans for improved temperature control.

Are you looking for a fast-acting portable heater for your living room, bedroom, or office? Convective ceramic heaters offer quick heat-up, adjustable fan speeds, and programmable settings for precise comfort. Many models are compact and lightweight, making them perfect for moving from room to room or for under-desk heating at workstations. For buyers comparing “best ceramic space heaters” or “top-rated energy-efficient electric heaters,” convective ceramic models consistently rank high for safety and versatility.

-

Radiant Ceramic Heaters

Radiant ceramic heaters are designed to emit infrared heat rather than relying on air movement. They radiate energy directly to objects and people within their line of sight, providing rapid, targeted warmth. Radiant ceramic infrared heaters are ideal for spot heating, zone heating in large open spaces, or environments where airflow is limited or undesirable. You’ll often find radiant ceramic heaters used in industrial plants, warehouses, garages, outdoor patios, and construction sites. For buyers looking to maintain comfort in specific areas without raising the temperature of the entire room, radiant ceramic heaters offer an efficient, energy-saving solution.

If you’re searching for “best radiant heater for workshops” or “infrared ceramic heater for outdoor patios,” radiant ceramic models are engineered for delivering instant, focused heat. Their silent operation and ability to minimize air movement make them ideal for allergy sufferers, laboratories, or settings where airborne dust must be controlled.

Materials in Ceramic Heaters: What Are They Made Of?

When evaluating ceramic heaters, you’ll want to understand "What materials are used in ceramic heater elements?" as material choices affect efficiency, longevity, and safety. The core heating elements in ceramic heaters are engineered for optimal performance and reliability, typically falling into two main categories:

-

Ceramic Fin Heaters

In ceramic fin heaters, high-purity ceramic blocks are bonded to aluminum or steel fins. When electrical current passes through the ceramic, it heats up rapidly, transferring thermal energy to the attached fins. The increased surface area provided by the fins allows for more efficient heat transfer to the surrounding air, making these heaters especially effective for convection-style heating. Ceramic fin heater elements are used extensively in portable space heaters, HVAC supplemental systems, and even in specialized industrial ovens. Their robust construction enables reliable operation under continuous or heavy-duty use.

Buyers researching “ceramic fin heater suppliers” or “industrial ceramic heating elements” often prefer these models for their durability and suitability in demanding applications such as factory floor heating, commercial drying systems, and heavy-duty process heating.

-

Honeycomb Disk Heaters

Honeycomb disk ceramic heaters utilize a perforated block of ceramic, engineered into a honeycomb structure to maximize surface area and airflow. As air passes through the honeycomb’s small channels, it is heated very efficiently by the surrounding ceramic. This design offers a compact form factor, fast thermal response, and excellent energy efficiency, making it ideal for portable heaters, specialized process heating, and compact appliances. Honeycomb ceramic elements require fewer metal fins, resulting in lighter and more flexible heater configurations for residential and commercial use.

Searching for “compact ceramic heater for small spaces” or “high-efficiency honeycomb ceramic heating elements”? Honeycomb disk heaters are frequently chosen for their ability to deliver rapid, uniform heat in a small footprint, ideal for desktop heaters, personal comfort devices, and energy-saving home appliances.

How Do Ceramic Heaters Work? Understanding the Technology

Are you comparing different electric heater technologies and wondering, "How do ceramic heaters work?" Here’s a detailed look at the science and operation behind both main types of ceramic heaters:

Convective Ceramic Heater Operation

- Electricity flows through the PTC ceramic element, generating heat rapidly.

- The ceramic absorbs and retains heat, efficiently transferring it to surrounding metal fins.

- A high-speed fan draws in cool air and blows it across the heated ceramic and fins, resulting in rapid, even heating of the room or workspace.

- Advanced features may include oscillating fans for broader heat distribution, programmable thermostats for precise temperature control, and overheat protection for safety.

- Because the ceramic element self-regulates its temperature, the risk of overheating is minimized and energy consumption is reduced as the ambient temperature rises.

Radiant Ceramic Heater Operation

- Ceramic plates heat up as electricity passes through, emitting long-wavelength infrared radiation.

- This radiant energy directly warms objects, surfaces, and people within the heater’s coverage area—ideal for spot and zone heating applications.

- Heat is delivered instantly, with almost no loss to the surrounding air, making radiant ceramic heaters extremely efficient for targeted comfort in open or drafty areas.

- Because radiant ceramic heaters don’t rely on fans, they operate silently and do not stir up dust or allergens, making them a top choice for allergy sufferers and quiet environments.

- The warmth persists on heated surfaces even after the heater is powered off, improving overall comfort and energy efficiency.

Want to see how ceramic heaters compare to oil-filled radiators, quartz heaters, or mica panel heaters? Explore our FAQ section below, or search for “ceramic vs oil-filled heater efficiency” and “best type of electric heater for allergy sufferers.”

Key Benefits of Ceramic Heaters: Why Choose Ceramic Heating?

Wondering, "Are ceramic heaters a good investment?" Review the core advantages that set ceramic heaters apart from other electric and fuel-based heating solutions:

- Energy Efficiency: Self-regulating PTC ceramic elements reduce power consumption as they heat up, making ceramic heaters among the most energy-efficient space heaters and process heaters available. Look for models with eco modes and programmable timers for additional savings.

- Rapid Warm-Up: Ceramic heaters reach optimal operating temperature within seconds, delivering quick comfort and eliminating the long preheat periods associated with oil-filled radiators or baseboard heaters.

- Enhanced Safety Features: Cool-touch exteriors, overheat protection, and tip-over switches dramatically reduce fire risk and burn hazards, making ceramic heaters a safer choice for homes with children or pets.

- Portability and Compact Design: Many ceramic heaters are lightweight and portable, with integrated handles or wheels for easy relocation. Their compact size allows for flexible placement in small rooms, offices, dorms, or workshops.

- Quiet Operation: Especially in radiant models, ceramic heaters maintain a low noise profile, allowing for undisturbed sleep, work, or study. This makes them ideal for bedrooms, libraries, and conference rooms.

- Advanced Controls: Digital thermostats, remote controls, programmable timers, and multiple power settings offer precision control over comfort and energy use. Some models even feature WiFi connectivity or smart home integration.

- Versatility: Ceramic heating technology adapts to a broad range of applications—from personal space heating to industrial drying, laboratory equipment, and even medical devices—thanks to its efficiency, controllability, and safety.

- Low Maintenance: With durable ceramic elements and minimal moving parts, ceramic heaters require less maintenance than oil, gas, or traditional electric resistance heaters, reducing total cost of ownership.

- Long Lifespan: High-quality ceramic heating elements are built to last, often delivering years of reliable service with proper care.

- Customizable Features: Many industrial ceramic heaters can be fitted with thermocouples, advanced controllers, and automation interfaces for precise process temperature management.

- Eco-Friendly: Ceramic heaters run on electricity, producing no emissions or indoor air pollutants—ideal for energy-conscious and health-focused buyers.

For users asking “Are ceramic heaters safe for bedrooms?” or “Can I use a ceramic heater in a nursery or children’s room?”—the answer is yes, due to their advanced safety mechanisms and cool-touch designs. For those focused on sustainability, ceramic heaters are also a strong option as part of a green or energy-saving home improvement strategy.

Common Applications of Ceramic Heaters: Use Cases by Industry

Are you asking, "Where are ceramic heaters used?" or "What industries benefit from ceramic heating technology?" Explore these common and specialized applications to understand how ceramic heaters provide reliable thermal solutions in almost every sector:

- Residential Space Heating: Portable ceramic room heaters are favorites for personal comfort in bedrooms, living rooms, bathrooms, dormitories, and apartments. Their safety features make them ideal for family households.

- Commercial Buildings: Office spaces, retail stores, churches, and classrooms rely on ceramic heaters for supplemental heating, zone control, and rapid warm-up during cold seasons.

- Manufacturing and Industrial Processing: Ceramic heating elements are crucial for plastic thermoforming, vacuum forming, PVC lamination, welding, and shrink-fitting. They are also used for drying, baking, and curing processes in industries ranging from automotive and aerospace to rubber, textiles, and electronics.

- Textile and Paper Drying: Fast, uniform moisture removal from synthetic fibers (such as Nylon, Perlon) or paper coatings is enabled by high-performance ceramic heaters in continuous production lines.

- Automotive and Metalworking: Ceramic heaters are used to preheat metal parts, cure paints and lacquers, and heat adhesives or epoxies in assembly lines and repair facilities.

- Laboratory and Medical Equipment: Accurate, reliable ceramic heating elements are found in sterilizers, incubators, laboratory ovens, and diagnostic equipment where precise temperature control is critical.

- Food Processing: Baking, drying, and temperature maintenance in food production lines often rely on industrial ceramic heaters for consistent, controllable heat without contamination risks.

- HVAC and Environmental Systems: Many modern HVAC systems integrate ceramic heaters for space heating, dehumidification, and freeze protection in sensitive environments.

- Outdoor and Hospitality: Powerful radiant ceramic heaters extend patio season for restaurants, event venues, and public spaces by delivering spot heating in open-air settings.

- Electronics: Soldering tools, circuit board preheaters, and chip manufacturing processes often use compact ceramic heating modules for rapid, targeted heat application.

- Custom and Niche Applications: Ceramic heaters also serve unique roles in 3D printers, aquarium heaters, reptile habitats, and more.

Looking for “best ceramic heater for garage workshops,” “industrial ceramic heater for manufacturing,” or “safe heater for pet enclosures”? These use cases highlight the adaptability of ceramic heating technology in both everyday and specialized settings.

How to Choose the Best Ceramic Heater: Expert Buying Guide and Decision Factors

Are you evaluating the best ceramic heater for your particular situation? Consider these critical buying factors and specifications to find the heater that matches your needs and priorities. Whether you’re shopping for a portable ceramic heater for a small bedroom, a wall-mounted unit for an office, or an industrial ceramic heating system for manufacturing, the right decision depends on aligning features with your unique requirements.

- Heating Capacity: Assess the wattage and BTU output relative to your space size or process requirements. Use online calculators or product specs to determine the appropriate capacity for bedrooms, living rooms, offices, or industrial zones.

- Heating Technology: Choose between convective (fan-forced) and radiant (infrared) ceramic heaters based on your desired application—whole-room heating versus spot or zone heating.

- Portability and Mounting: Decide if you need a freestanding portable heater, wall-mounted unit, under-desk heater, or a fixed installation for your facility. Consider features like carrying handles, caster wheels, or easy wall mounting.

- Safety Features: Look for overheat protection, tip-over switches, cool-touch exteriors, and certifications from UL, ETL, or similar safety organizations. These features are especially important for residential and public environments.

- Controls and Convenience: Digital thermostats, remote controls, programmable timers, and adjustable fan speeds add comfort and flexibility. Some smart ceramic heaters integrate with WiFi or smart home systems for automation.

- Noise Level: If you require silent operation, opt for radiant ceramic heaters or review decibel ratings for fan-driven models. User reviews can provide real-world noise insights.

- Energy Efficiency: Prioritize heaters with PTC ceramic elements, eco modes, and automatic shut-off to reduce energy costs and environmental impact.

- Durability and Warranty: For industrial or commercial buyers, robust construction, quality components, and long-term warranties are essential for reliability and cost-effectiveness.

- Price and Value: Balance upfront price with expected lifetime, energy savings, maintenance needs, and included features. Read product reviews and comparisons to gauge overall value.

- Special Features: Consider integration with air filtration, oscillation, humidification, or smart controls if your application demands added comfort or convenience.

Need help comparing ceramic heater models or brands? Use our supplier directory or try search queries like "best ceramic heater for large rooms," "energy efficient ceramic heater reviews," "industrial ceramic heating systems," or "portable ceramic space heater buying guide" to discover top-rated products and expert recommendations.

Choosing the Right Ceramic Heater Supplier: Source with Confidence

To ensure maximum performance, safety, and support, it’s crucial to source ceramic heaters from reputable, experienced suppliers and manufacturers. Here’s how to streamline your selection and purchasing process:

- Access our directory of ceramic heater suppliers for a curated list of leading manufacturers, distributors, and custom solution providers.

- View detailed business profile pages to evaluate each company’s technical expertise, product range, industry certifications (such as ISO 9001), and project experience.

- Contact suppliers directly through integrated forms for technical advice, product literature, or custom quotes tailored to your application.

- Leverage our patented website previewer to quickly browse supplier websites, product catalogs, and customer testimonials for added confidence.

- Utilize the Request for Quote (RFQ) tool to solicit competitive quotes from multiple ceramic heater vendors, saving time and optimizing value.

- Compare after-sales support, warranty terms, spare parts availability, and delivery options to ensure a seamless procurement experience.

Not sure which supplier is right for you? Try searches such as "top ceramic heater manufacturers," "custom PTC ceramic heater element suppliers," "industrial ceramic heating solutions," or "energy efficient ceramic heater distributors" for more detailed company overviews and industry reviews.

Frequently Asked Questions About Ceramic Heaters

Are ceramic heaters energy efficient compared to other electric heaters?

Yes, ceramic heaters typically outperform standard wire coil or oil-filled radiators in energy efficiency, especially those with PTC elements that automatically adjust power usage as the ambient temperature rises. Their rapid heat-up and self-regulating features help minimize wasted electricity and lower utility bills. For maximum efficiency, look for ENERGY STAR certified ceramic heater models or those with programmable eco settings.

Are ceramic heaters safe to use overnight or unattended?

Most modern ceramic heaters are engineered with safety in mind, featuring tip-over switches, overheat protection, and cool-touch housings. Always follow manufacturer instructions, avoid blocking air inlets/exhausts, and keep flammable materials away. While many models are designed for safe overnight operation, using smart plugs or timers adds another layer of safety for peace of mind.

Do ceramic heaters produce odors, fumes, or emissions?

Ceramic heaters do not produce combustion byproducts, fumes, or unpleasant odors during operation, making them an excellent choice for people with allergies, asthma, or chemical sensitivities. Their clean electric operation means zero indoor air pollution and no risk of carbon monoxide.

What maintenance do ceramic heaters require?

Maintenance is simple: periodically inspect your ceramic heater for dust or debris buildup, especially around intake/exhaust grills, and wipe clean with a soft cloth. Check electrical cords and safety features regularly, and store the heater in a dry location when not in use. Most ceramic heaters are designed for years of trouble-free use with minimal upkeep.

How long do ceramic heating elements last?

High-quality ceramic heating elements can last for 5–10 years or more with normal use, thanks to their robust, oxidation-resistant construction. Actual lifespan depends on usage, environment, and care. Many reputable brands offer multi-year warranties for added assurance. If you’re sourcing industrial or custom ceramic heaters, ask about rated service life and replacement part availability.

How do ceramic heaters compare to oil-filled, quartz, or mica panel heaters?

Ceramic heaters typically offer faster heat-up times, better safety features, and more compact designs than oil-filled radiators. Compared to quartz or mica panel heaters, ceramic models often provide superior energy efficiency, quieter operation, and greater flexibility for spot or whole-room heating. For buyers seeking both safety and convenience, ceramic heaters are often the preferred choice.

Can ceramic heaters be used as primary heating systems?

While ceramic heaters excel as supplemental heat sources or for zone heating in homes and businesses, larger, high-wattage models or integrated ceramic heating systems can serve as primary heat in small to medium spaces, cabins, workshops, or energy-efficient buildings. For whole-house or industrial heating, consult with a supplier about system sizing and integration options.

What are the advantages of PTC ceramic heating elements?

PTC (Positive Temperature Coefficient) ceramic elements automatically regulate their temperature, enhancing both safety and energy efficiency. This self-limiting property prevents overheating, reduces fire risk, and lowers power consumption, making PTC ceramic heaters ideal for both residential and industrial heating applications.

Can ceramic heaters help reduce energy costs in the long term?

Absolutely. Due to their self-regulating ceramic elements and advanced controls, ceramic heaters can help lower long-term energy costs by running only as much as needed to maintain set temperatures. Pairing ceramic heaters with programmable timers, smart thermostats, or occupancy sensors can further optimize energy consumption for both home and business users.

Are there ceramic heaters with air purification or humidification features?

Yes, some advanced ceramic heaters integrate air purification (such as HEPA filters or ionizers) and/or humidification features. These models are ideal for buyers searching for “ceramic heater with air filter” or for those with respiratory sensitivities who want to improve indoor air quality while heating their space.

Where can I find reviews and comparisons of top ceramic heater models?

Explore our supplier directory for links to product reviews, buying guides, and expert comparisons of leading ceramic heater brands. You can also search for “best ceramic space heater reviews 2024,” “energy efficient ceramic heater comparison,” or “industrial ceramic heater ratings” to find recent evaluations and recommendations.

Conclusion: Why Choose a Ceramic Heater?

Ceramic heaters deliver a powerful combination of efficiency, safety, flexibility, and reliability—making them a top choice for today’s energy-conscious consumers, businesses, and industrial operators. Their unique ceramic heating technology provides rapid, even warmth, superior safety, and low maintenance, while supporting a broad spectrum of applications from personal comfort to precision manufacturing. Whether you’re outfitting your home, office, laboratory, or production line, ceramic heaters offer unmatched convenience, adaptability, and value.

Ready to find the perfect ceramic heater for your needs? Browse our supplier directory for trusted brands and top-rated products, or use search prompts like "best ceramic heater for workshops," "energy efficient ceramic space heater reviews," "custom industrial ceramic heating elements," or "portable ceramic room heater for apartments" to discover reviews, buying guides, and technical articles tailored to your application.

Still have questions? Explore our FAQ section above or contact leading ceramic heater manufacturers for custom recommendations, technical support, and detailed product specifications to ensure you choose the best solution for your project or facility.

Related Searches and Resources:

- Find ceramic heater suppliers and manufacturers

- Learn more about energy efficient space heating solutions

- Compare ceramic vs oil-filled vs infrared heaters

- Get tips for safe use of electric room heaters

- Discover industrial ceramic heater applications

Cartridge Heaters

Cartridge Heaters Industrial Electric Heaters

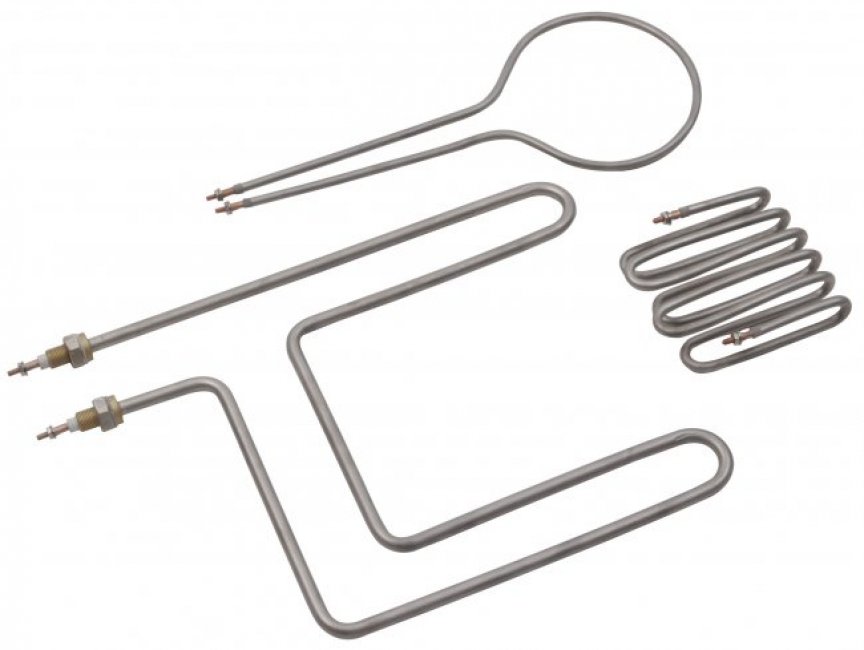

Industrial Electric Heaters Heating Elements

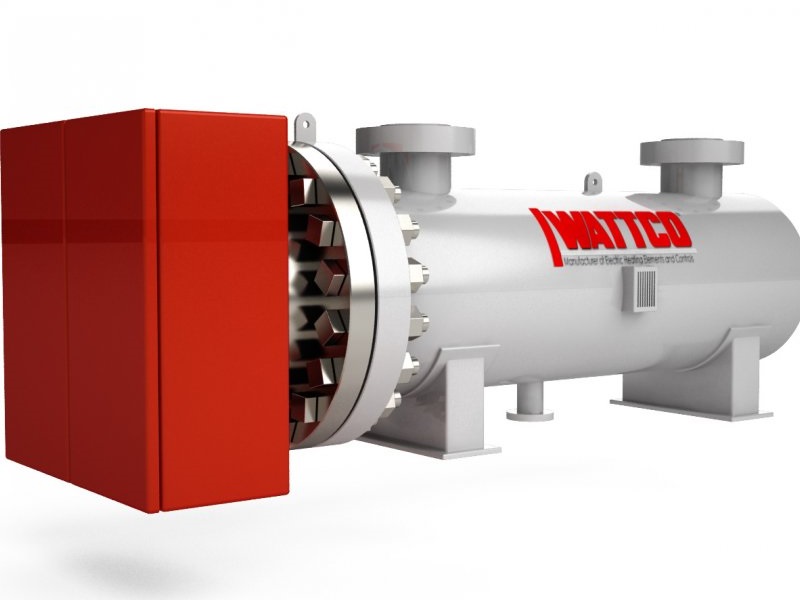

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services