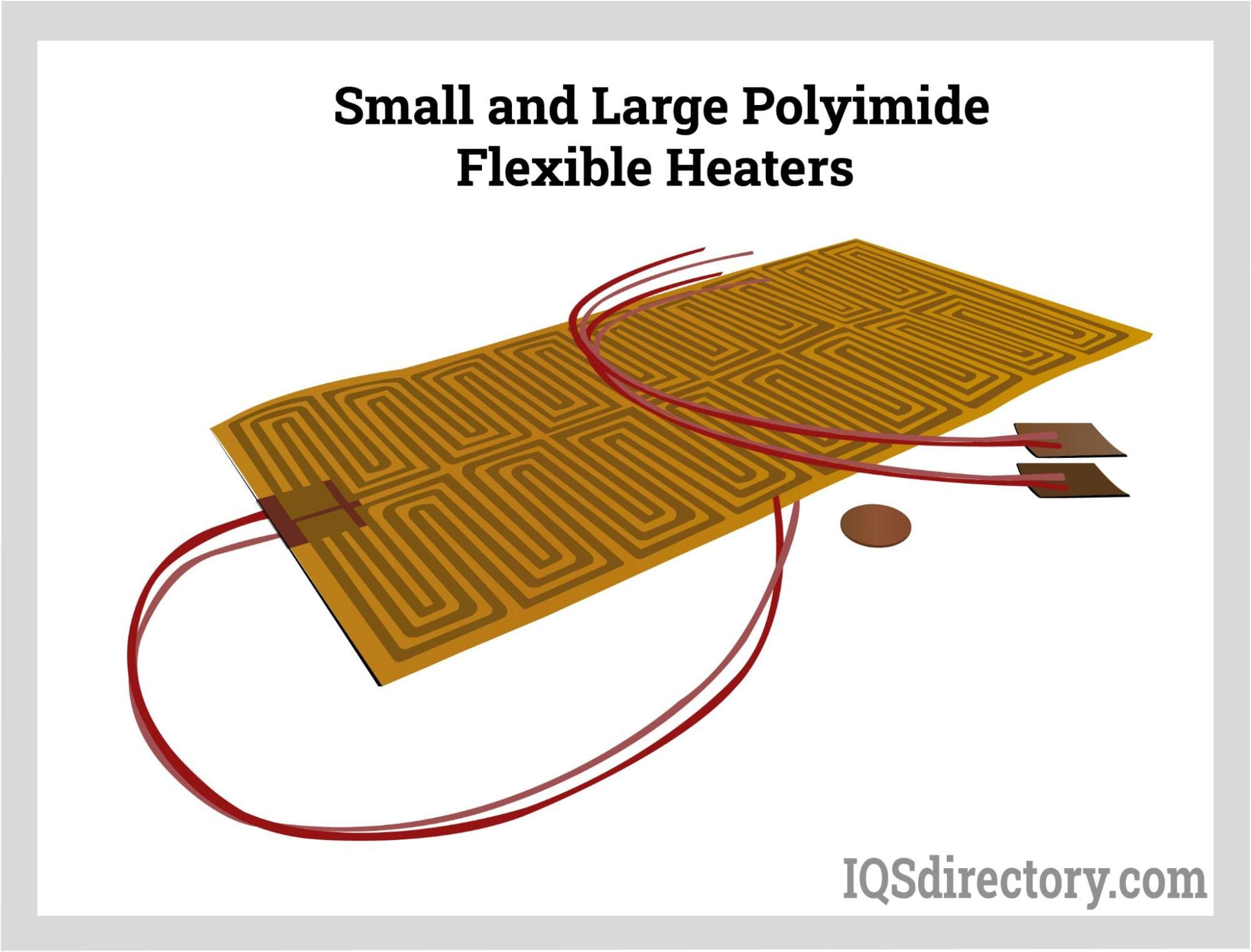

Most foil heaters are etched using an automated machine. The etching in the foil helps to distribute the heat evenly when the power source is turned on by putting more of the surface in contact with the device being heated. The computer-designed etched foil is sometimes manufactured with a laminated coating on either side to insulate it. Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

At Dalton Electric Heating Co., Inc., we are proud to be a leading provider of high-performance electric heaters, serving various industries with innovative and reliable heating solutions. For decades, we have focused on designing and manufacturing durable products, including cartridge heaters, industrial heaters, and other custom thermal solutions, all built to meet the most demanding industrial ...

At Ryan Herco Flow Solutions, we take pride in providing high-performance fluid handling and filtration products, and our electric heaters stand out as an essential part of that mission. We specialize in electric heating solutions designed to deliver precise temperature control, reliability, and safety across a wide range of applications

More Foil Heater Manufacturers

One of the many advantages of foil heaters is that they can heat up rapidly because the foil is highly conductive and very thin. The thin foil sheets can easily be integrated into products that need heating but do not have a lot of excess space.

A foil heater requires wider elements, but these elements can be spaced much closer together. Because of this, many elements can be added to the foil and run side by side, producing more heat in less space.

The foil in a foil heater is usually made out of aluminum, and a wire element is run through the foil to spread the heat. This element is covered by an insulating sleeve. Sometimes one side of the foil contains adhesive material so that it can be fixed to a flat surface in the application that it is being manufactured for. If the foil is flexible, the heater can be bent to match the angles of a particular shape.

Aluminum foil sheets can be cut in a variety of sizes, and many manufacturers offer custom prototype manufacturing to help companies who are in the product development stage. Once a successful prototype is created, a large number of foil heaters will be manufactured and shipped to another business where they are integrated into the product assembly line.

Foil heaters are used in many industries and they can be found in products like car battery warmers, cabinets, defrost applications, heated food tables, laboratory equipment, incubators, ceiling panels, and wall panels. Etched foil heaters are the solution of choice for engineers dealing with advanced thermal management applications that require heat but lack space. Electronic devices can be soldered directly to the foil, allowing for integrated control and display features.

Cartridge Heaters

Cartridge Heaters Industrial Electric Heaters

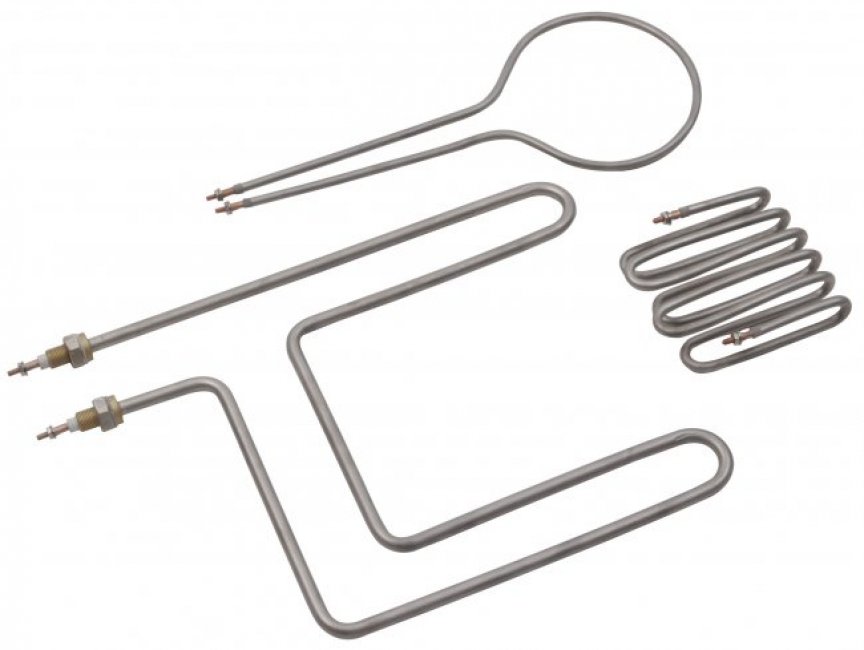

Industrial Electric Heaters Heating Elements

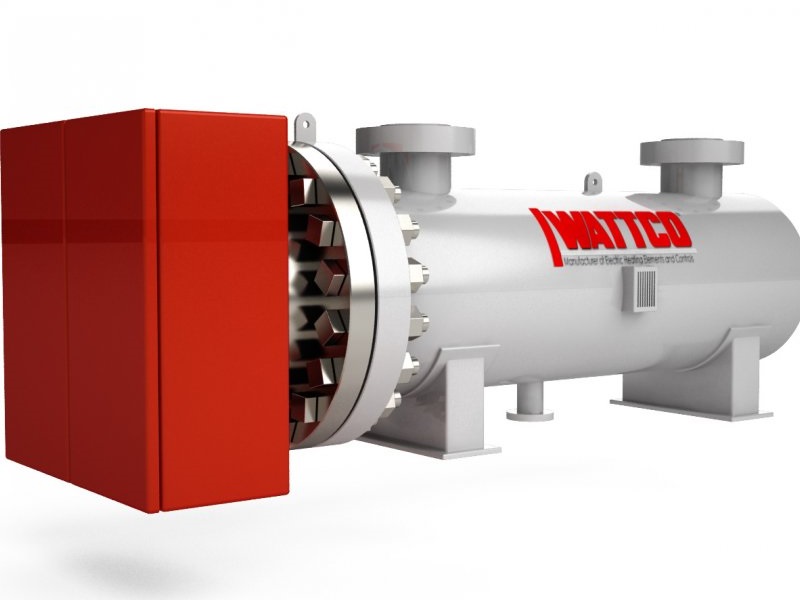

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services