Duct heaters work with existing central forced-air heating systems to preheat fresh air or returned air. The central air handler filters the air, re-heats it and blows it through the ductwork. The conditioned air is distributed throughout the building and is then returned to the central air handling unit (AHU). Read More…

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

At Dalton Electric Heating Co., Inc., we are proud to be a leading provider of high-performance electric heaters, serving various industries with innovative and reliable heating solutions. For decades, we have focused on designing and manufacturing durable products, including cartridge heaters, industrial heaters, and other custom thermal solutions, all built to meet the most demanding industrial ...

At Ryan Herco Flow Solutions, we take pride in providing high-performance fluid handling and filtration products, and our electric heaters stand out as an essential part of that mission. We specialize in electric heating solutions designed to deliver precise temperature control, reliability, and safety across a wide range of applications

More Duct Heater Manufacturers

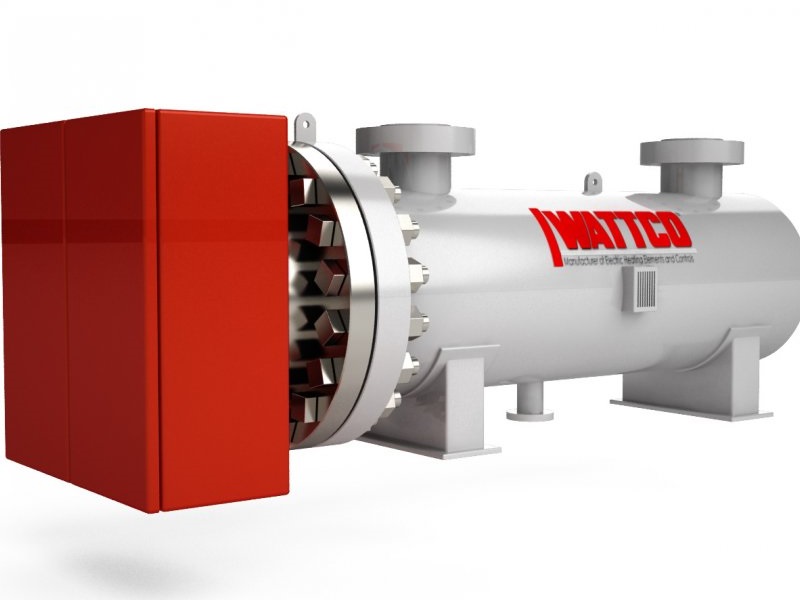

Electric heater manufacturers generally construct duct heaters in rectangular or square box configurations, but they can create rounded ones for the best fit in certain sheet metal ductwork.

Consisting of two major components, the heating elements and the electric terminal within the boxed framework, duct heaters can be bottom mounted, flange mounted, round collar mounted or slip-in and are easily installed in existing or new HVAC systems, with the heater control panel mounted in any convenient location.

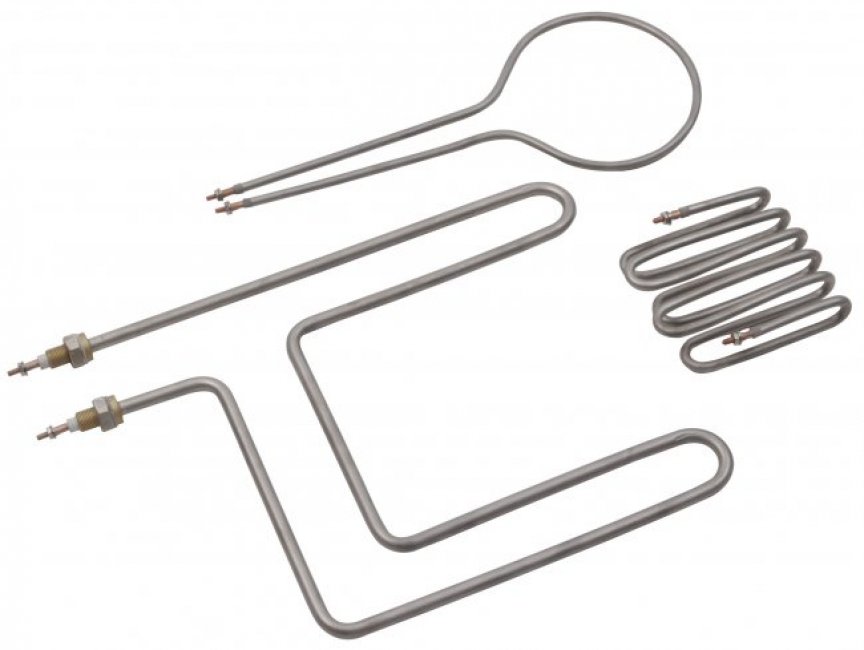

The two types of heating elements used in duct heaters are open coil and tubular (standard and finned), each offering certain advantages.

Open coil elements are coils of nickel chrome wire that are very popular due to excellent heat dissipation; however, tubular elements are more suited to demanding environments as they are sheathed with protective covers of metals such as aluminum, iron, stainless steel or steel.

Because of their sheathes, tubular elements are slower to respond but can hold up to humid and dusty atmospheres, and fins are used to help more quickly distribute the heat. Sheathed elements, especially finned varieties, offer a very long life with less maintenance and lower risk of fire and electric shock.

Choosing the right heating element, electrical components and controls is essential to achieving the highest economy and efficiency from a duct heater. Temperature sensing duct heaters can be encoded to regulate electric heat output based on a desired temperature, and modulating controllers can allow successful duct heater operation in even extremely low air flow. Plus, electronic enclosures act as moisture/debris resistant and explosion proof housings.

Cartridge Heaters

Cartridge Heaters Industrial Electric Heaters

Industrial Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services