A flexible heater is a wire wound, chemically etched, or screen-printed heater that can be bent or flexed to fit the curves of the surface that has to be heated. Many flexible heaters include transparent heaters, polyimide/Kapton® film heaters, carbon-printed heaters, and silicone rubber heaters (etched and wire wound). These heaters are available in a wide range of configurations, as they can alter the size, shape, and thickness, as well as additional components that can enhance the functionality of any application. Read More…

i-Heat designs and manufactures custom heating elements from a variety of materials. Our products include Silicone Rubber, Polyester Film, Kapton® Polyimide, High Temperature, Mica, Ceramic and Enclosures Heaters. We manufacture drop-in sub-assemblies with sensors, thermostats, fuses, cords and plugs.

Backer Hotwatt is a superior designer & manufacturer of electric heaters and related heater accessories for various OEM & industrial applications.

For more than 70 years, Ulanet™ has been engineering and manufacturing electric heaters, cartridge heaters, immersion heaters, tubular heaters, miniature strip heaters and bolt hole heaters, as well as industrial heaters and appliance thermostats.

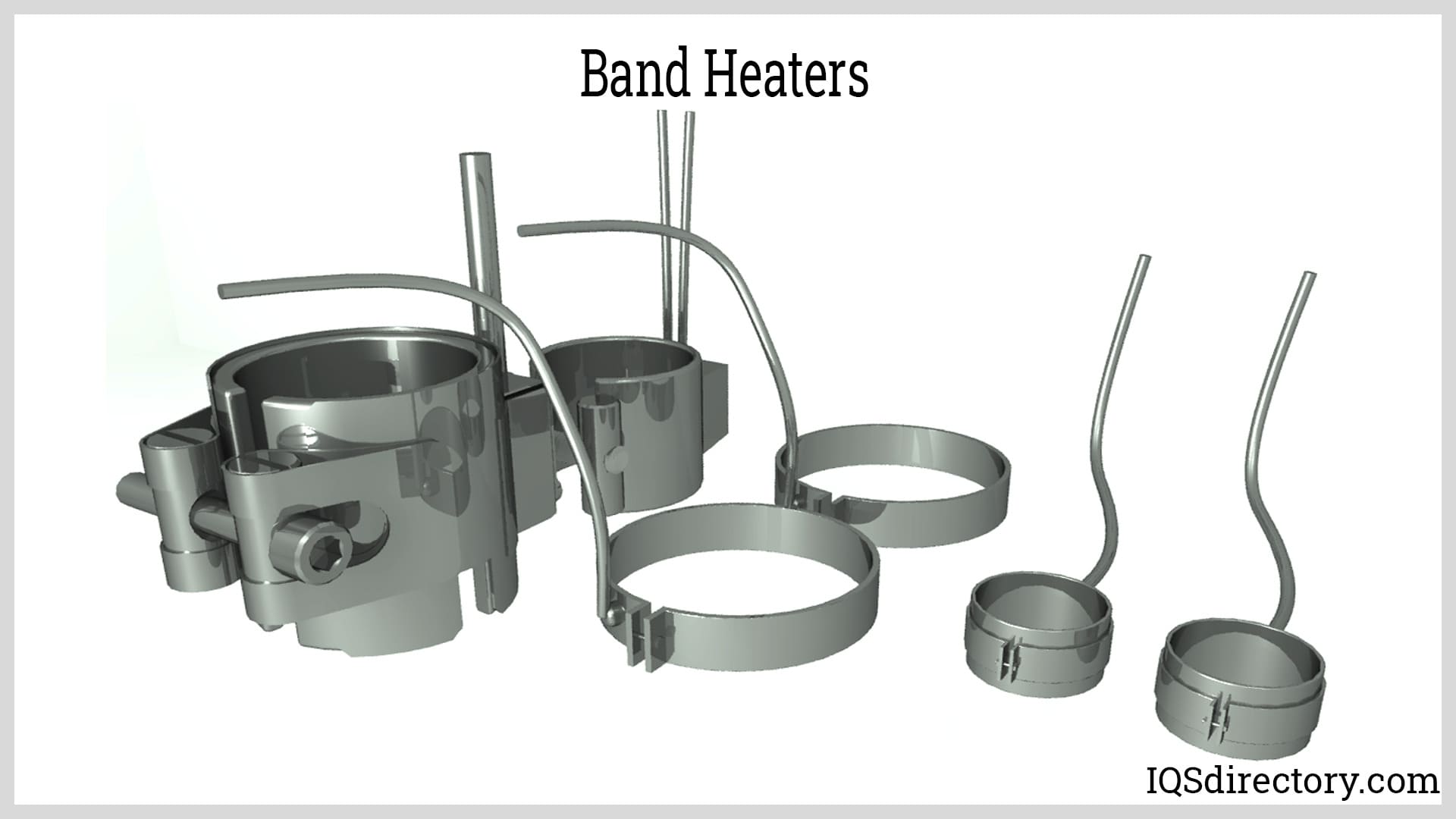

Backer Marathon is your premier manufacturer of electric heaters and a wide range of other heating components. Our inventory includes cartridge heaters, band heaters, coil heaters, and more. We have thousands of standard electric heater models, and our engineers are capable if designing a custom heater for more complex specifications. No matter what component you require, Backer Marathon is...

More Flexible Heater Manufacturers

Flexible heaters offer characteristics that make them resistant to chemicals and moisture and are durable, dependable, accurate, and efficient. Flexible heating elements are used in industrial, military, and commercial applications because they may be easily bonded or attached to any kind and size of the substrate, including being actively flexed in an application. The most effective way to ensure thermal energy leaves the heating element is to directly adhere flexible heaters to the surface that needs to be heated. Heating with flexible heaters is the best method if the heater is correctly installed and built such that there is a uniform interface between the heater and the substrate to be heated.

Various sensors and controls can frequently be integrated directly into the flexible heater. Flexible heater designs frequently use pre-set or programmable thermostats, thermocouples, thermistors, RTDs, thermal fuses, and other electronic components.

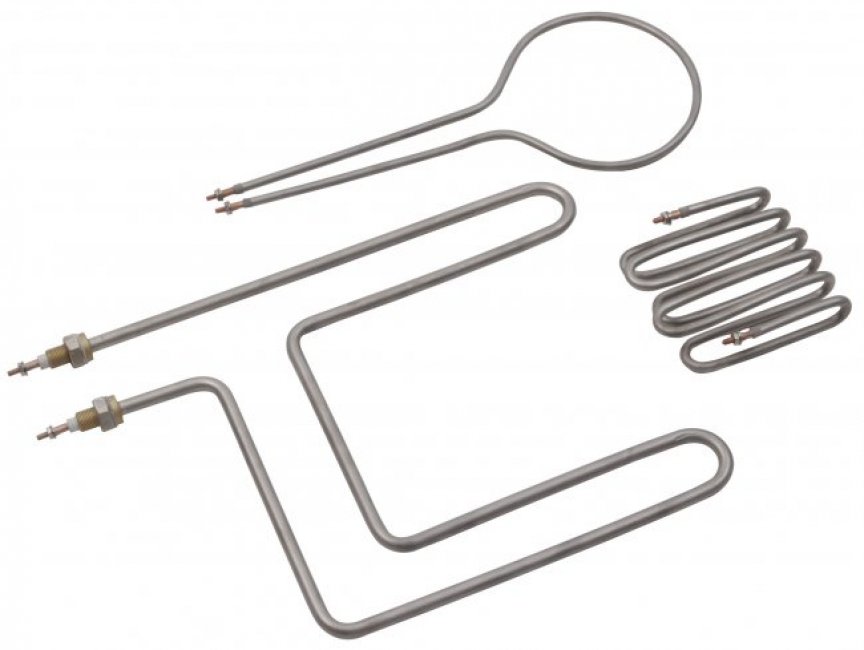

Types of Flexible Heaters

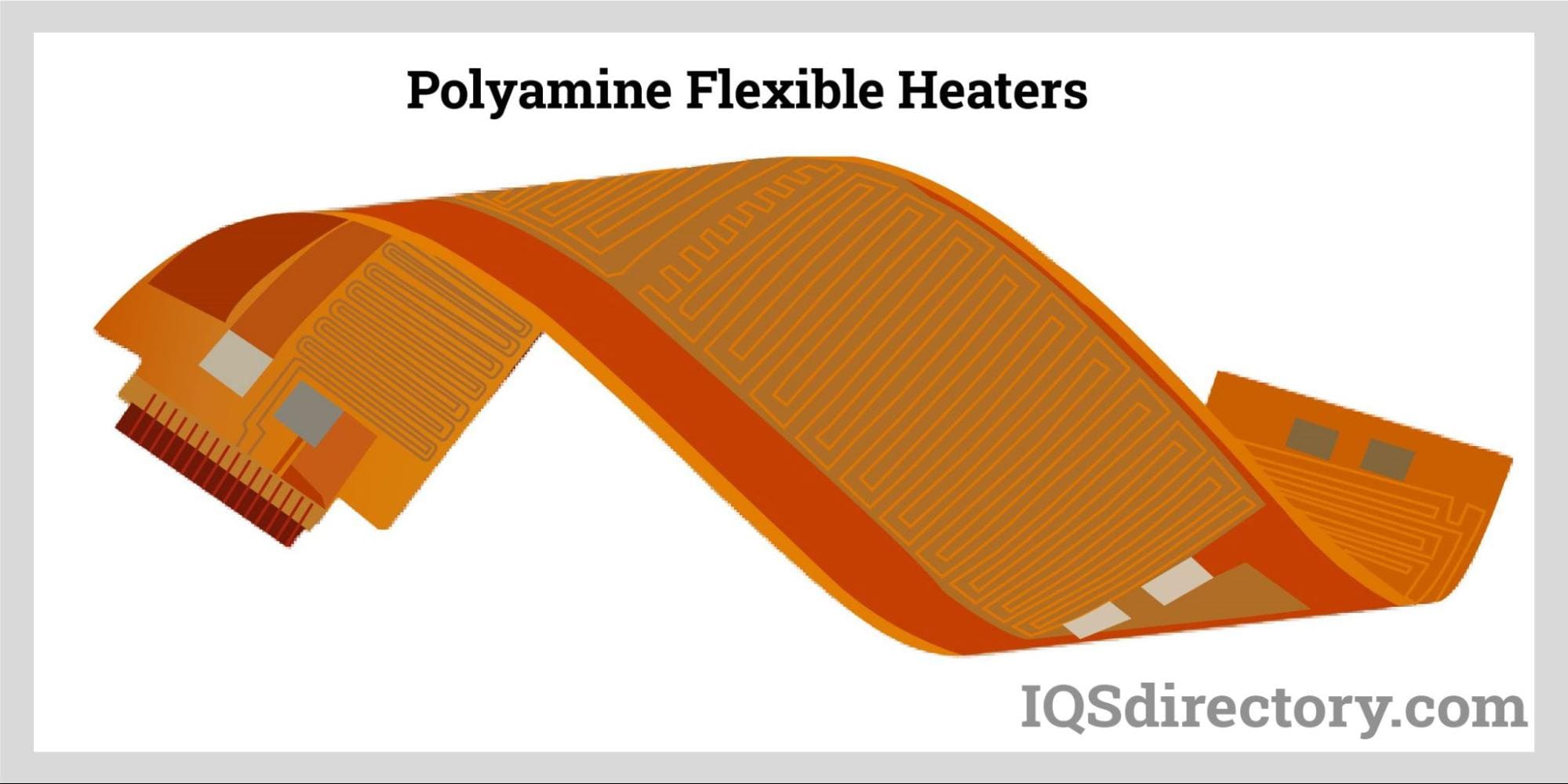

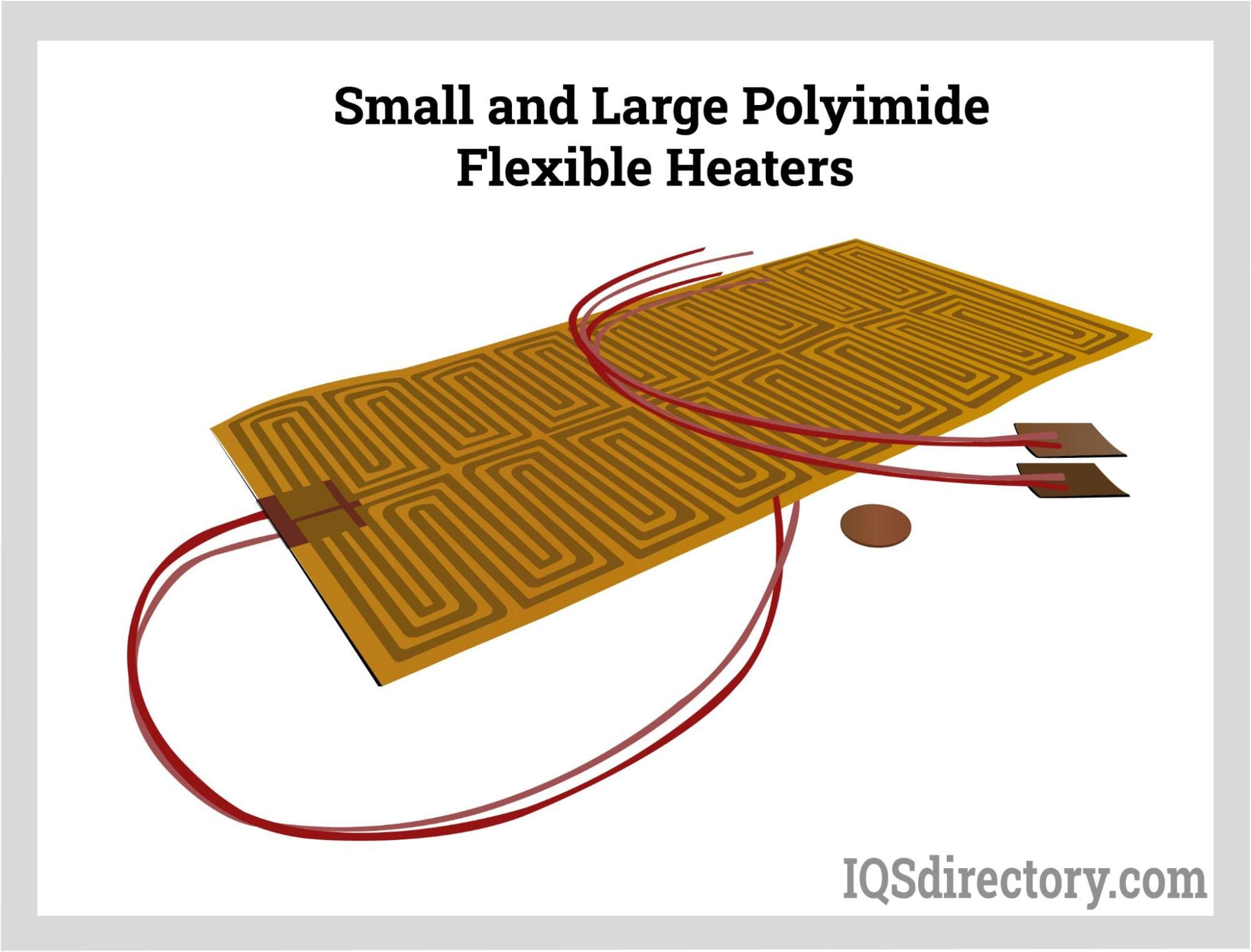

Polyimide Heaters

Polyimide is a thin, light polymer film with exceptional tensile strength, tear resistance, and dimensional stability. Since it has been used for flexible PCBs for more than 30 years, this material offers low outgassing in a vacuum and resistance to radiation, fungi, and various other chemicals when utilized in heater applications. In addition, the etched foil element has high circuit pattern repeatability because photo imaging technology decreases production costs and improves heat transfer. Flexible heating elements can be placed very closely to one another, creating increased surface area.

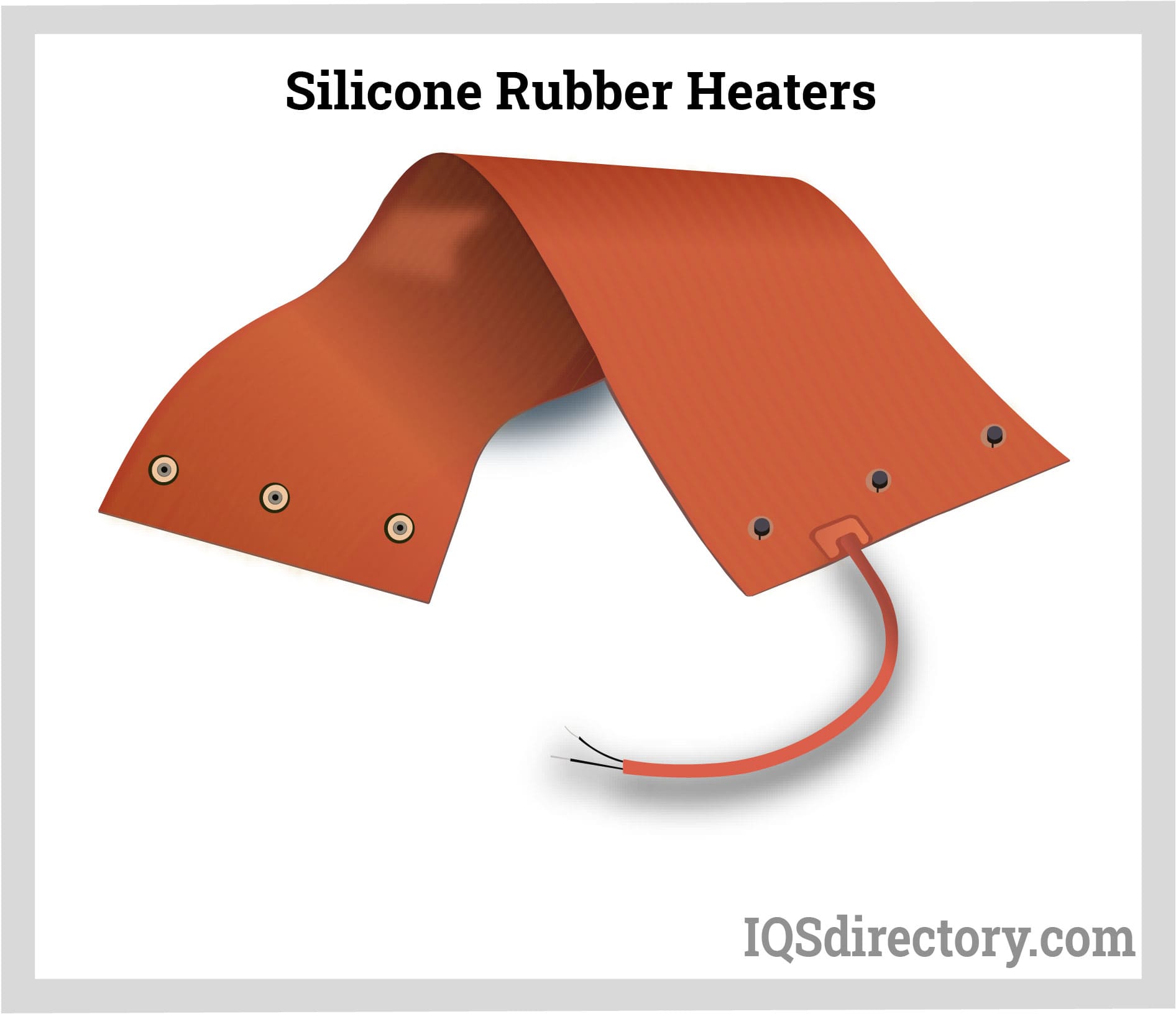

Silicone Rubber Heaters

Silicone rubber heaters give dimensional stability and effective heat transfer capabilities without sacrificing flexibility; an etched circuit or wire-wrapped heating element is placed between fiberglass-reinforced silicone rubber. The internal foil of an etched foil heater may be the same as that of a polyimide heater. Still, silicone rubber offers reliable wear protection from mechanical damage and is more likely to be utilized in wet situations because of its tough properties.

Using mechanical fasteners, such as latch fasteners, boot hooks, grommets, snap fasteners, springs, and lacing cords, is also made possible by silicone rubber. Any design can benefit from adding additional heat distribution and thermal shielding components, most frequently silicone sponge and aluminum.

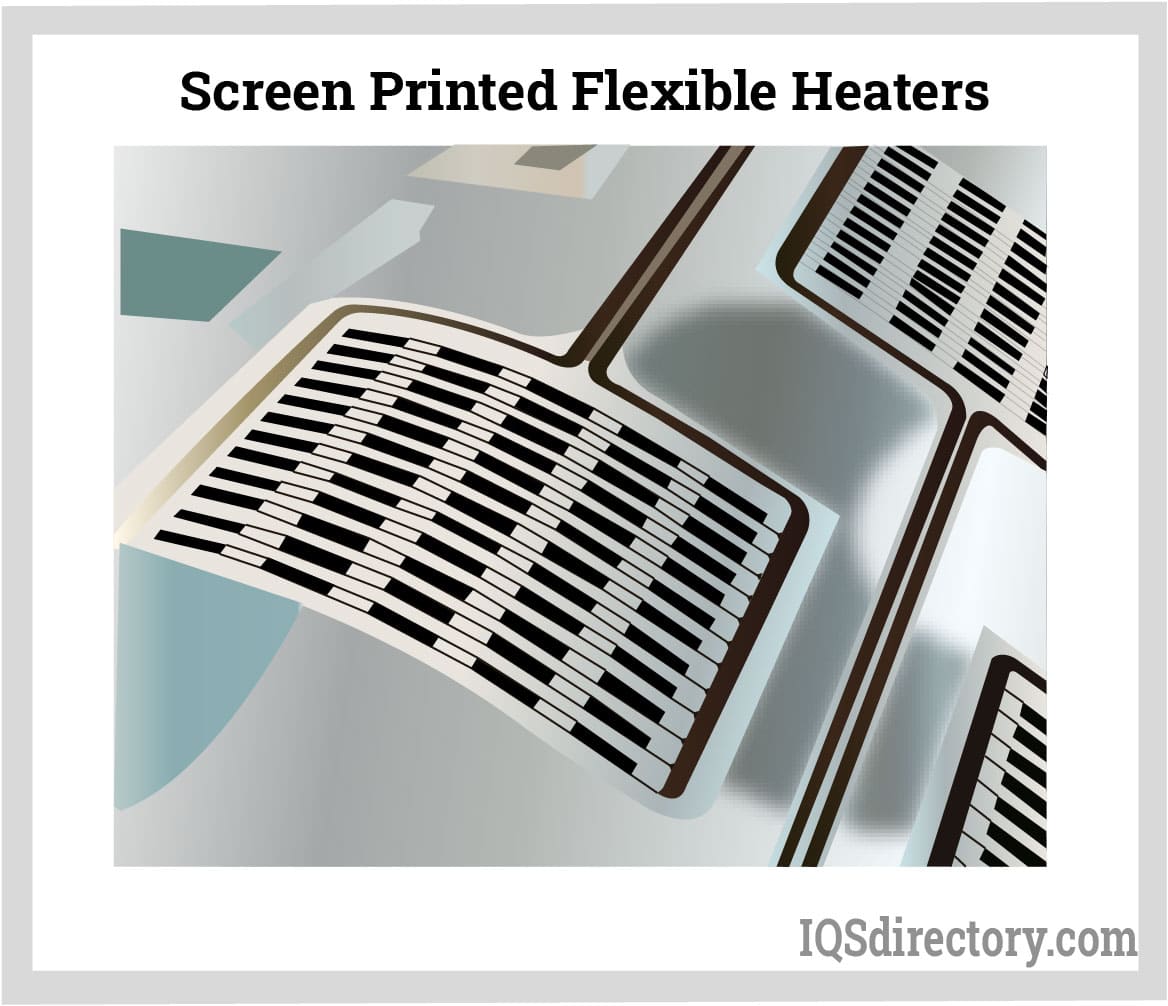

Screen-Printed Heaters

Screen-printed heaters are created using special screen-printed ink onto a flexible substrate, such as polyester (PET), polyimide (PI), polycarbonate, and several others. Flexible screen-printed heaters can be made with ink that enables the heater to regulate its temperature or as fixed resistance heater designs that require a thermal control circuit to manage the temperature. These warmers are used frequently in the automotive sector to prevent ice from forming on side-view mirrors of vehicles, buses, and lorries.

Flexible silicone heaters are resilient, trustworthy, precise, and resistant to chemicals and moisture. They are glued or attached to other system components. Screen-printed heating elements have many industrial, commercial, and military uses where dependability, economic considerations, minimum cross-section, resistance to deterioration, and fundamental flexibility are crucial.

Applications of Flexible Heaters

The Transportation Industry

Self-regulating flexible silicone heaters are vulcanized to different parts of transportation systems to prevent ice build-up during winters on moving parts of trains and transit systems.

Vacuum Environments

Spacecraft and satellites require vacuum conditions to operate and maintain these systems; efficient temperature control is needed to maintain a vacuum environment with no air. Flexible heaters help maintain the desired temperature in vacuum environments because they are directly attached to vital, temperature-dependent systems.

Batteries and Electronics in Sub-Zero Temperatures

Flexible heaters are vulcanized onto battery surfaces to help maintain their proper operating temperature range.

Medical Devices

Flexible heating systems are integrated into medical assemblies to maintain a specific temperature or range of temperatures in medical devices such as blood analyzers and small catheters.

Heat Transfer in Consumer Electronics

Flexible heaters are bonded to heat sinks to ensure proper heat transfer in consumer electronics like PlayStations® and mobile phones. In addition, they are often integrated with sensors to detect an increase in temperature.

The Advantages of Flexible Heaters

The benefits of flexible heaters include:

- Resistant to chemicals and moisture

- Easy to bond to any surface

- Flexible and thin form factor

- Cost-efficient

- Over a wide temperature range, flexible heaters have strong thermal stability.

The Disadvantages of Flexible Heaters

The drawbacks of using flexible heaters include the following aspects:

- Sharp radius bend limitations

- Different temperature restrictions apply to flexible heaters made of polyimide and silicone.

- Silicone costs more than certain other heater types, such as aluminum foil.

- It may fail if suddenly pinched or folded.

Choosing the Proper Flexible Heater Supplier

To make sure you have the most constructive outcome when purchasing a flexible heater from a flexible heater supplier, it is important to compare several companies using our directory of flexible heater suppliers. Each flexible heater company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each flexible heater company website using our proprietary website previewer for an understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple flexible heater companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

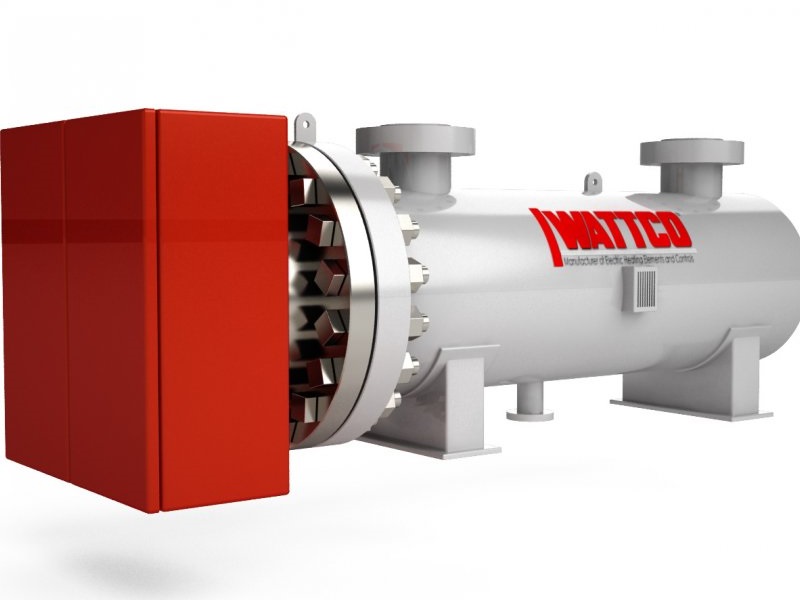

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services